A client recently inquired about the appropriate rubber expansion joint for the following working conditions:

-

Diameter: DN65

-

Pressure: 1.6 MPa

-

Temperature: 88–100°C

-

Medium: Water with 37 Vol.% Ethylene Glycol

So, how can we ensure longer service life under these conditions?

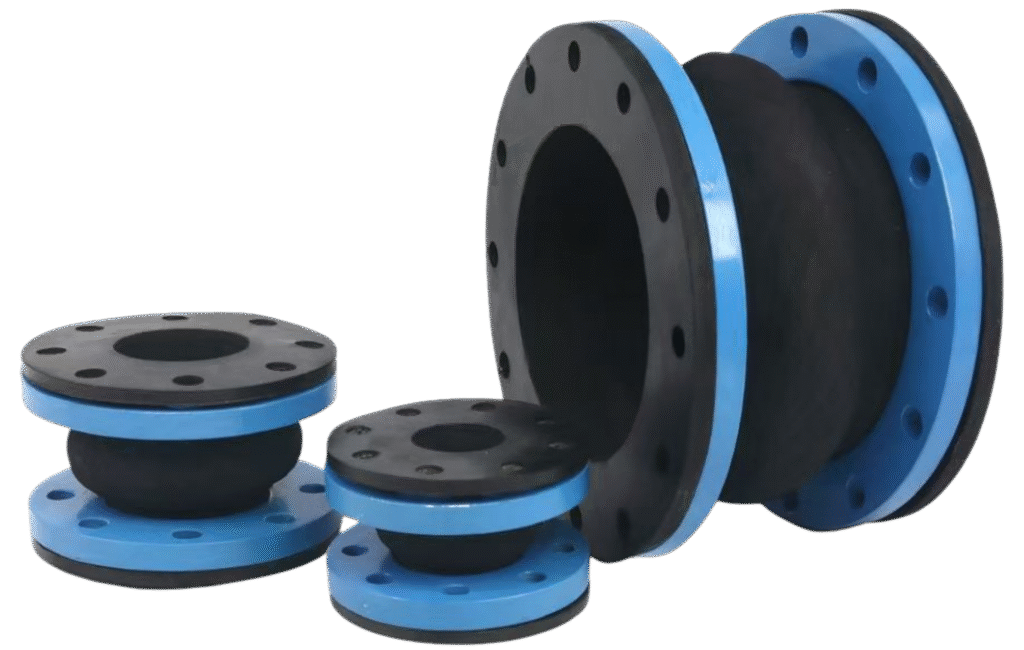

Recommended Solution: Nitrile Rubber Expansion Joint (NBR)

For media containing ethylene glycol or water-glycol mixtures, the best option is an oil-resistant rubber expansion joint, specifically one made from nitrile rubber (NBR). However, the quality of the rubber is crucial.

At Shanghai Songjiang Group, all oil-resistant rubber joints are manufactured using premium N41 nitrile rubber, with an NBR content of approximately 50%. Both the inner lining, reinforcement layer, and outer rubber are entirely made from high-quality nitrile, ensuring superior resistance to glycol-based media and high temperatures.

Common Misconception: Standard Market NBR Joints

Client Follow-up Question:

Can I just buy a regular oil-resistant rubber joint from the market?

Answer:

We do not recommend standard market options unless you can verify the full material composition. Most common rubber joints labeled as “oil-resistant” have:

-

An inner layer with less than 10% NBR content

-

A reinforcement and outer layer made from generic rubber

Such joints are not suitable for high-temperature glycol applications and may degrade rapidly, leading to system failure.

Why Not Use PTFE-Lined Joints?

Client Follow-up Question:

Some manufacturers suggest PTFE-lining. Is that a better option?

Answer:

No, not in this case. While PTFE-lined expansion joints do perform well under low-temperature and highly corrosive environments, they are not suitable for high-temperature applications like 88–100°C. At elevated temperatures, the PTFE liner becomes prone to deformation or rupture, potentially causing:

-

Flow blockage in the pipeline

-

PTFE liner detachment or cracking

Therefore, NBR is the safer and more durable choice for this specific application.

Conclusion

For ethylene glycol media at elevated temperatures, always select a high-quality nitrile rubber expansion joint with verified NBR content. Songjiang Group’s oil-resistant joints, made with 50% N41 nitrile rubber throughout, provide the durability and chemical resistance necessary for long-term performance.