Shanghai Songjiang Vibration Absorber Co., Ltd. Official Website presents a technical article regarding the roughness of the inner diameter of rubber expansion joints. The following is a written response from the Songjiangflex technical department to customer feedback regarding concerns about the inner diameter roughness and its potential impact on product quality.

Manufacturing Process and Mold Information

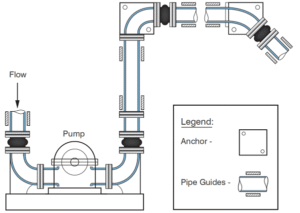

Before vulcanization, rubber expansion joints are placed into molds. The outer shell mold is made of metal, while the inner diameter mold is made of rubber, also known as the “rubber bladder mold” or “inflated mold” in the industry.

The outer shell mold is made of tool steel, with a typical lifespan of 3 to 5 years. Over time, the metal mold surface inevitably experiences wear and tear, which may leave visible marks on the rubber expansion joint after vulcanization. These marks are not a sign of incomplete vulcanization; rather, they are impressions left from the contact with the metal mold. These impressions do not affect the product’s performance or quality, and they have no impact on its service life.

The inner diameter mold is made from aging-resistant rubber and typically lasts around 100 uses for smaller sizes. For larger sizes (DN300 and above), the lifespan is reduced to around 50 uses, and for DN500 and above, the lifespan is approximately 20 uses. These rubber bladder molds do have a limited lifespan. For instance, small-diameter rubber bladders can be used up to 100 times, and after about 80 uses, surface cracking may occur. These cracks on the rubber bladder surface will imprint on the inner diameter of the rubber expansion joint.

Impact on Quality and Performance

The surface cracks and marks created by the rubber bladder during vulcanization are natural occurrences in the production process. When the bladder reaches the end of its usable life, the next batch of rubber expansion joints will likely exhibit similar surface patterns. These marks will not flake off, nor will they impact the product’s quality or performance. Additionally, they will not affect the service life of the expansion joint.