PTFE Expansion Joint

Home > PTFE Expansion Joint

PTFE Expansion Joint

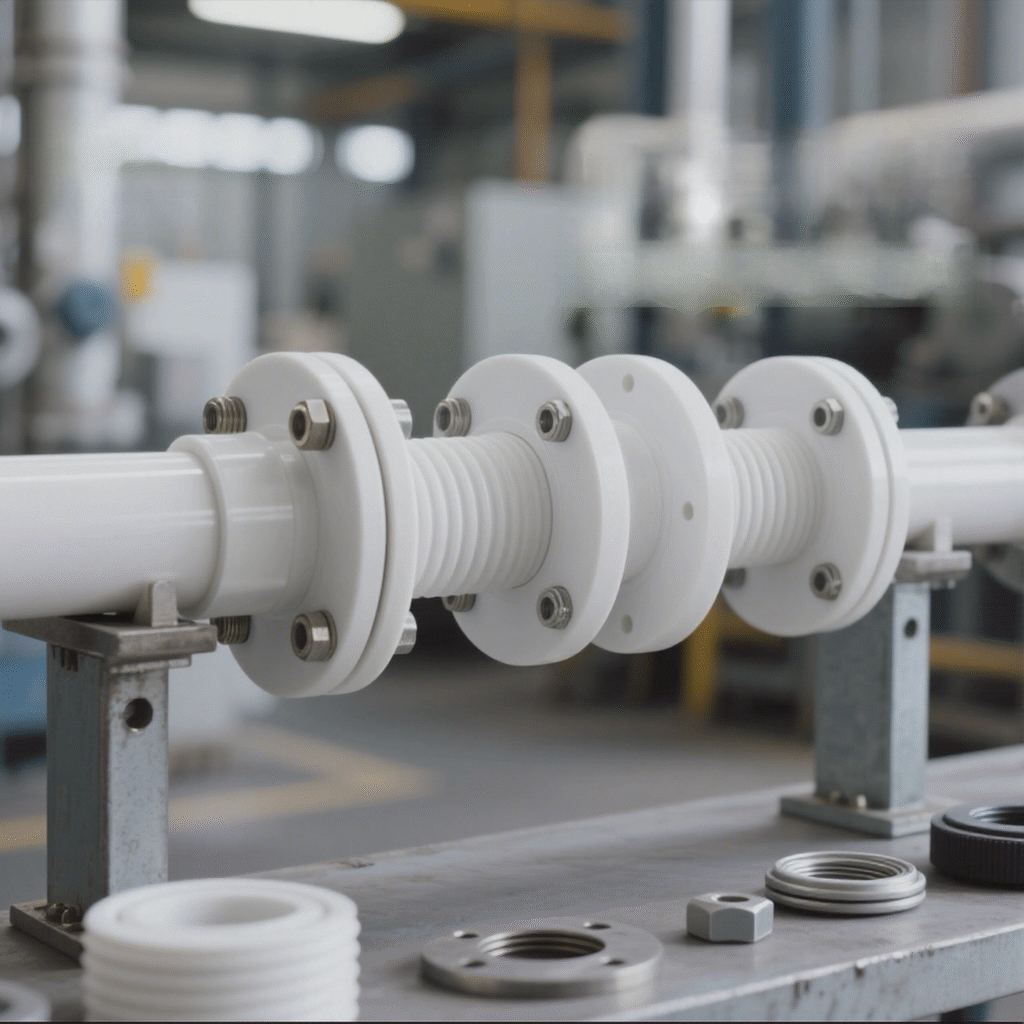

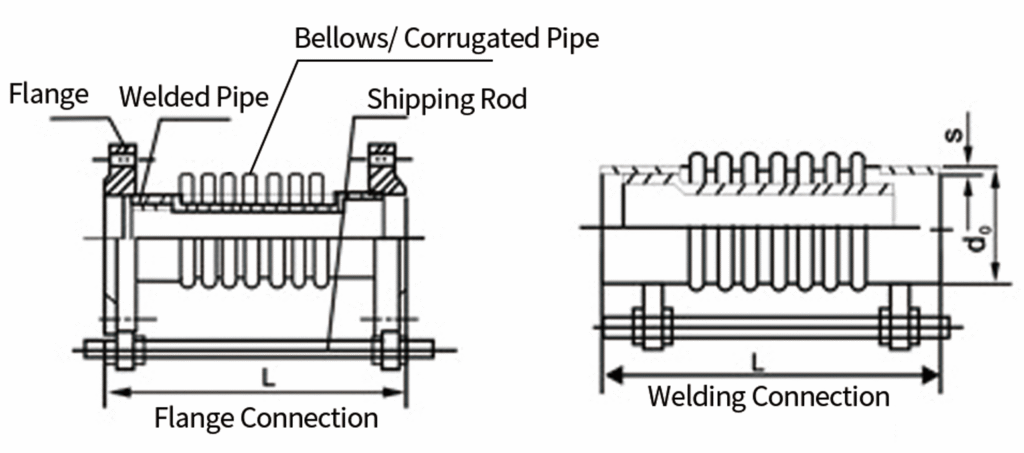

The BGF type PTFE bellows expansion joint features multi-convolution PTFE construction reinforced with metal rings, offering high pressure resistance, excellent corrosion protection, and reliable sealing. With fully PTFE-covered flanges and built-in limit rods, it ensures long service life and effective movement compensation in complex piping systems.

BGF Type PTFE Bellows Expansion Joint Product Introduction

The BGF type PTFE bellows expansion joint features an advanced design consisting of 2, 3, or 5 molded white PTFE convolutions. Each convolution is reinforced with metal rings, significantly enhancing the pressure-bearing capacity and overall structural stability of the bellows, ensuring excellent sealing performance and durability even under high-pressure conditions.

This product is equipped with standard galvanized carbon steel flanges, which are fully covered by the lips of the PTFE bellows. This design effectively prevents the medium from directly contacting the metal surfaces, achieving complete isolation between the medium and metal. As a result, all surfaces exposed to the medium are made of corrosion-resistant PTFE material, greatly extending the product’s service life. It is especially suitable for piping systems that transport corrosive media.

To ensure safe operation and facilitate installation, the BGF expansion joint comes factory-installed with steel limit rods that restrict excessive expansion and contraction during operation, protecting the piping system from damage caused by excessive displacement. Additionally, the increased number of convolutions not only improves the joint’s pressure resistance but also significantly enhances its movement compensation capabilities, effectively absorbing axial, lateral, and angular displacements to meet the multi-directional movement compensation needs of complex piping systems.

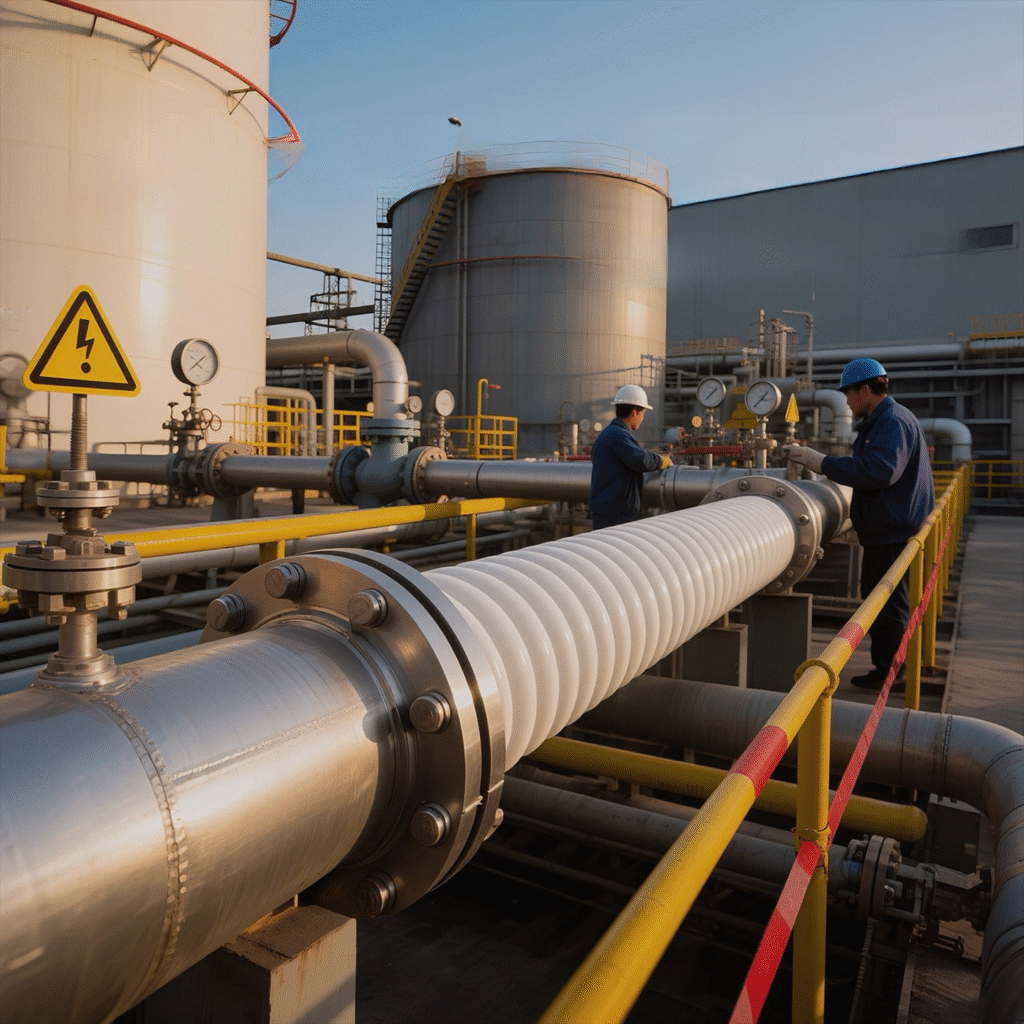

The right side shows our Songjiang PTFE expansion joint installed in a chemical pipeline application.

PTFE Corrugated Hose:The Ultimate Solution for High-Temperature and Corrosive Applications

1

Discover the Power of PTFE Corrugated Hoses

When it comes to transporting highly corrosive gases or liquids at extreme temperatures, ordinary hoses just can’t handle the challenge. That’s where PTFE corrugated hoses (Polytetrafluoroethylene, also known as F4 hoses) excel. Designed with precision and manufactured using high-quality extrusion techniques, PTFE hoses combine durability, flexibility, and exceptional chemical resistance.

2

Why Choose PTFE Corrugated Hoses?

Extreme Temperature Resistance: PTFE hoses operate reliably from -60°C to +260°C (-76°F to 500°F), making them ideal for both high-temperature industrial processes and cryogenic applications.

Corrosion Resistance: Chemically inert to most acids, alkalis, water, and organic solvents, these hoses outperform traditional hoses in aggressive chemical environments.

Mechanical Strength: Even at -196°C, PTFE hoses maintain excellent flexibility and elongation, ensuring durability in harsh conditions.

High Pressure & Vacuum Handling: Capable of withstanding positive pressures up to 1.6 MPa and vacuum pressures down to 77 kPa, PTFE hoses adapt to demanding industrial needs.

Non-Stick & Low Friction: With minimal surface tension and exceptional lubricity, these hoses prevent material buildup and improve flow efficiency.

Biologically Safe: Non-toxic and inert, PTFE hoses are suitable for medical and food-grade applications, including long-term contact with human tissue.

3

PTFE corrugated hoses are widely used in:

- Chemical Processing: Resistant to strong acids and alkalis.

-

Pharmaceutical & Medical: Safe for cleanroom and medical device applications.

-

Aerospace & Defense: Reliable under extreme temperature fluctuations.

-

Food & Beverage: Ensures non-contamination of liquids.

-

Electrical & Electronics: Acts as insulation and chemical protection for sensitive components.

- With unmatched temperature tolerance, chemical resistance, and mechanical flexibility, PTFE corrugated hoses are the ultimate choice for industries where safety, durability, and performance are critical. Upgrade your piping systems today and experience the advantages of PTFE technology.

PTFE Expansion Joint – Standard Dimensions

| Nominal Diameter | Total Length (mm) | Bellows Caliber (mm) | Wave Number | Wall Thickness (mm) | Compensation ±△ (mm) | Flange Thickness (mm) | Number of Tie Rods |

|---|---|---|---|---|---|---|---|

| DN25 | 110 | 32 | 8 | 0.4 | 20 | 16 | 2 |

| DN32 | 130 | 40 | 8 | 0.4 | 20 | 18 | 2 |

| DN40 | 130 | 48 | 8 | 0.5 | 20 | 18 | 3 |

| DN50 | 145 | 57 | 8 | 0.5 | 20 | 19 | 3 |

| DN65 | 180 | 76 | 8 | 0.6 | 25 | 20 | 3 |

| DN80 | 180 | 89 | 8 | 0.6 | 25 | 20 | 3 |

| DN100 | 200 | 108 | 8 | 0.6 | 25 | 22 | 3 |

| DN125 | 230 | 133 | 8 | 0.8 | 25 | 22 | 3 |

| DN150 | 240 | 159 | 8 | 0.8 | 30 | 24 | 3 |

| DN200 | 340 | 219 | 8 | 1.0 | 30 | 26 | 3 |

| DN250 | 330 | 273 | 6 | 1.2 | 30 | 29 | 3 |

| DN300 | 370 | 325 | 6 | 1.5 | 30 | 32 | 3 |

| DN350 | 370 | 377 | 6 | 2.0 | 30 | 35 | 4 |

| DN400 | 425 | 426 | 6 | 2.0 | 30 | 38 | 4 |

| DN450 | 460 | 480 | 6 | 1.0×2 | 40 | 42 | 4 |

| DN500 | 440 | 530 | 5 | 1.2×2 | 50 | 46 | 5 |

| DN600 | 420 | 630 | 4 | 1.2×2 | 50 | 52 | 5 |

| DN700 | 440 | 720 | 4 | 1.5×2 | 50 | 63 | 5 |

| DN800 | 490 | 820 | 4 | 1.5×2 | 50 | 74 | 5 |

| DN900 | 520 | 920 | 4 | 2.0×2 | 50 | 82 | 6 |

| DN1000 | 540 | 1020 | 4 | 2.0×2 | 50 | 90 | 6 |

| DN1200 | 550 | 1220 | 4 | 2.0×2 | 45 | 95 | 6 |

Note: The PTFE lining is typically 1–2 mm thick, but the thickness may vary depending on the model. If you have specific requirements for thickness, material, or chemical compatibility, feel free to contact us for customized solutions.