Braided Flexible Connector

Home > Braided Flexible Connector

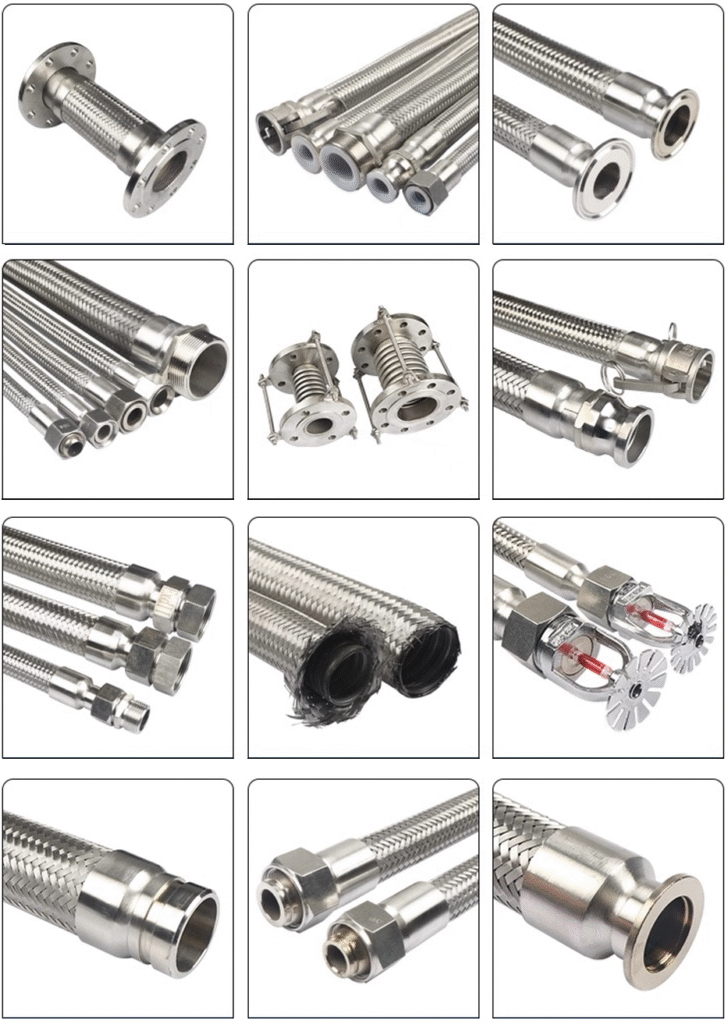

Introduction of Braided Flexible Connector/Stainless Steel Braided Mental Hose

A Braided Flexible Connector, also known as a stainless steel braided metal hose, is a high-quality flexible pipe joint used in various industrial pipeline systems. It mainly consists of three parts: Inner corrugated tube: A thin-walled circular stainless steel tube that provides excellent flexibility and vibration absorption. Outer braided mesh: Made of stainless steel wire or strip woven according to specific parameters, which enhances pressure resistance and protects the corrugated tube. Flange ends: Available as fixed, loose, or one fixed and one loose flange, making installation easier. This type of flexible connector is widely used to absorb pipeline vibration, compensate for slight misalignments, reduce noise, and protect sensitive equipment from vibration-induced damage. It plays a crucial role in ensuring the long-term reliability of piping systems.

Stainless steel bellows consist of an inner corrugated tube, a metal braided mesh, clamps, and the chosen connection method. We usually classify them according to the type of connection, such as welded type, ferrule type, male-thread type, flange type, and quick-coupling type.

Classification by Connection Type

① Flanged End (Rotating / Fixed)

Widely used in large-diameter pipelines

Easy installation without twisting the hose

Available in carbon steel or stainless-steel flanges

② Threaded End (BSP / NPT)

Suitable for small-diameter connections

Includes male/female threads

Used in HVAC, pump connections, gas lines

③ Welded End

Butt weld or socket weld

Ensures strong sealing performance

Used for high-temperature and high-pressure environments

④ Quick Coupling Type

Camlock couplings, fire-fighting couplings, clamp type

Fast and reliable installation

Used for oil, chemicals, and emergency pipelines

What Are the Key Features of Braided Flexible Connector?

Excellent flexibility and displacement compensation: Can absorb axial, lateral, and angular displacements caused by thermal expansion or slight misalignment during installation.

Outstanding vibration and noise reduction: Minimizes vibration transmission from pumps, compressors, or other equipment to the pipeline.

Superior corrosion resistance: Inner hose and outer braid can be made of stainless steel 304, 316, or 321, suitable for water, chemicals, oils, and more.

High temperature and pressure resistance: Suitable for demanding working environments up to 2.5 MPa.

Easy and flexible installation: Flanges can be customized (fixed or loose), making disassembly and maintenance convenient.

Compact structure and lightweight: Saves installation space and reduces the load on the pipeline system.

Where Are Braided Flexible Connectors Commonly Used?

Braided flexible connectors are widely applied in industries such as:

Food and beverage pipelines

Potable water supply systems

Pharmaceutical and medical industries

Chemical and petrochemical plants

Hydraulic systems

HVAC systems and building services

They are ideal for systems where vibration isolation, thermal movement absorption, or noise reduction is needed.

How to Select the Right Braided Flexible Connector?

Pressure range: Available in 1.0 MPa, 1.6 MPa, and 2.5 MPa, 5.0 MPaoptions. Select the appropriate pressure rating based on your system’s working conditions.

Material selection: Choose 304 for general use, 316 for higher corrosion resistance, and 321 for better heat resistance.

Flange style: Decide between fixed flanges, loose flanges, or a combination (one fixed and one loose) depending on installation space and maintenance needs.

Movement requirements: Choose the appropriate length and offset capacity to ensure effective vibration absorption and avoid overextension.

What Are the Technical Parameters of Braided Flexible Connector?

| Specification (DN) | Size (in) | Length (mm) | Offset (mm) | Braided Mesh/Belt Type | Limit (pcs) |

|---|---|---|---|---|---|

| DN25 | 1 | 300 | 34 | Single Layer Metal Mesh | / |

| DN32 | 1-1/4 | 300 | 33 | Single Layer Metal Mesh | / |

| DN40 | 1-1/2 | 300 | 32 | Single Layer Metal Mesh | / |

| DN50 | 2 | 300 | 24 | Single Layer Metal Mesh | / |

| DN65 | 2-1/2 | 300 | 24 | Single Layer Metal Mesh | / |

| DN80 | 3 | 300 | 25 | Single Layer Metal Mesh | / |

| DN100 | 4 | 300 | 22 | Single Layer Metal Mesh | / |

| DN125 | 5 | 300 | 17 | Single Layer Metal Mesh | / |

| DN150 | 6 | 300 | 14 | Single Layer Metal Mesh | / |

| DN200 | 8 | 300 | 5 | Single Layer Metal Mesh | / |

| DN250 | 10 | 300 | 5.5 | Double Layer Metal Mesh | 4 |

| DN300 | 12 | 300 | 5 | Double Layer Metal Mesh | 4 |

| DN350 | 14 | 300 | 5 | Double Layer Metal Mesh | 4 |

| DN400 | 16 | 400 | 5 | Double Layer Steel Belt | 4 |

| DN450 | 18 | 400 | 5 | Double Layer Steel Belt | 5 |

| DN500 | 20 | 400 | 5 | Double Layer Steel Belt | 5 |

| DN600 | 24 | 500 | 4 | Double Layer Steel Belt | 5 |

| DN700 | 28 | 600 | 4 | Double Layer Steel Belt | 5 |

All expansion joint products can be customized according to actual project requirements, including dimensions, materials, temperature range, and accessory configuration, to meet the specific installation and operational needs of different duct systems.