MENTAL EXPANSION JOINT

PRODUCT > MENTAL EXPANSION JOINT

What is a Mental Expansion Joint?

A Metal Expansion Joint, also known as a Metallic Expansion Joint or Stainless Steel Bellows, is a flexible compensating device installed in piping systems to absorb:

thermal expansion and contraction

vibration from pumps or equipment

pressure fluctuations

misalignment between pipes

It is typically made of stainless steel bellows formed through hydroforming or roll-forming, and can come with flanges, weld ends, tie rods, or covers depending on the application.

Metal expansion joints are widely used in industries such as:

power plants/HVAC systems/petrochemical plants/shipbuilding/industrial pipelines/exhaust and ventilation systems

They ensure the safe operation of pipelines by reducing stress and protecting equipment.

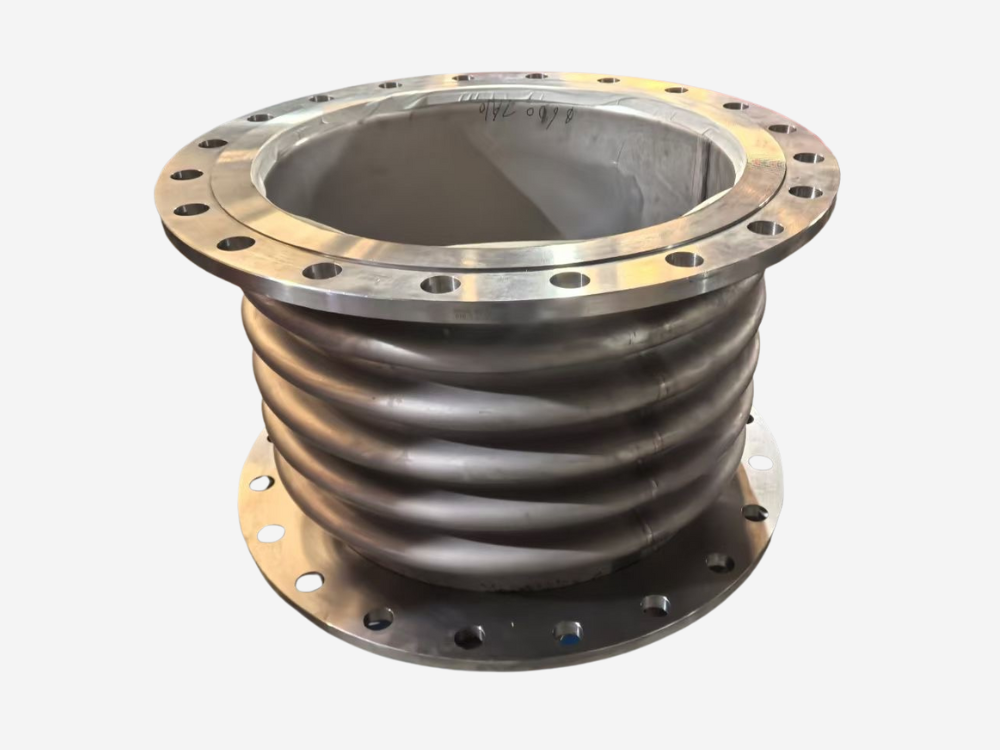

Factory Production of SS Bellows

The photo on the right shows our daily production of metal bellows in our manufacturing workshop. Every unit is welded and tested according to international standards to ensure reliable performance in vibration absorption and thermal expansion compensation.

Mental Expansion Joint Classifications

Mental expansion joints, commonly made from stainless steel bellows or metal hoses, are essential components in piping systems that absorb thermal expansion, vibration, and mechanical movement. These joints can be classified based on their design and application: axial, lateral, and angular expansion joints. Axial joints accommodate changes along the pipe axis, lateral joints handle side-to-side movement, and angular joints allow bending or rotational displacement. Choosing the correct type ensures system safety, longevity, and optimal performance in industries such as power plants, chemical plants, and shipbuilding.

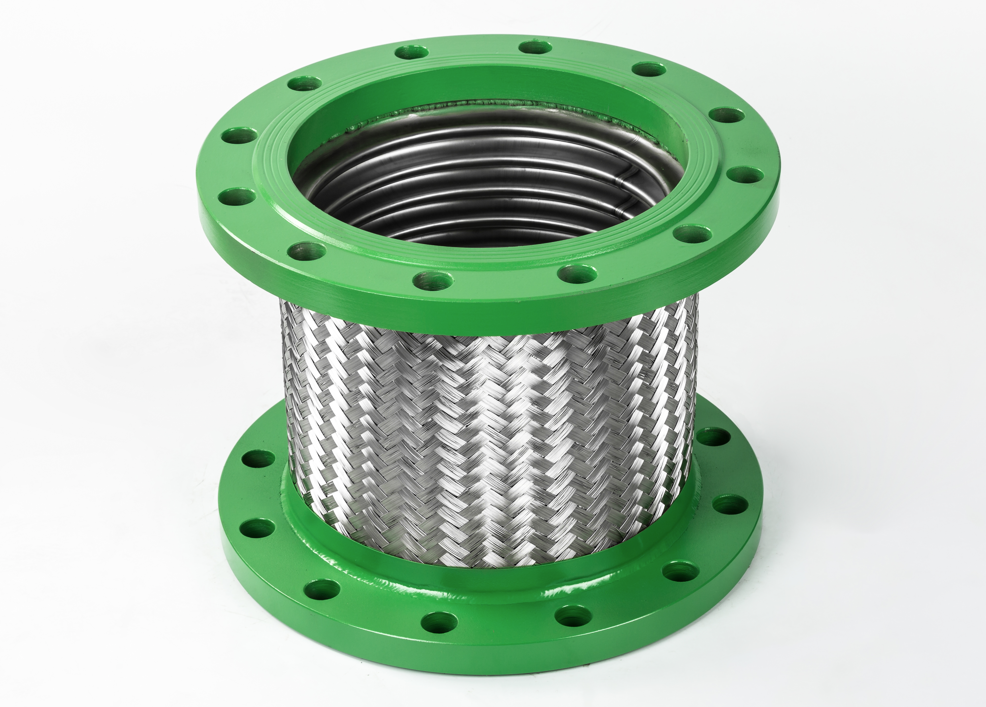

Corrugated Expansion Joint

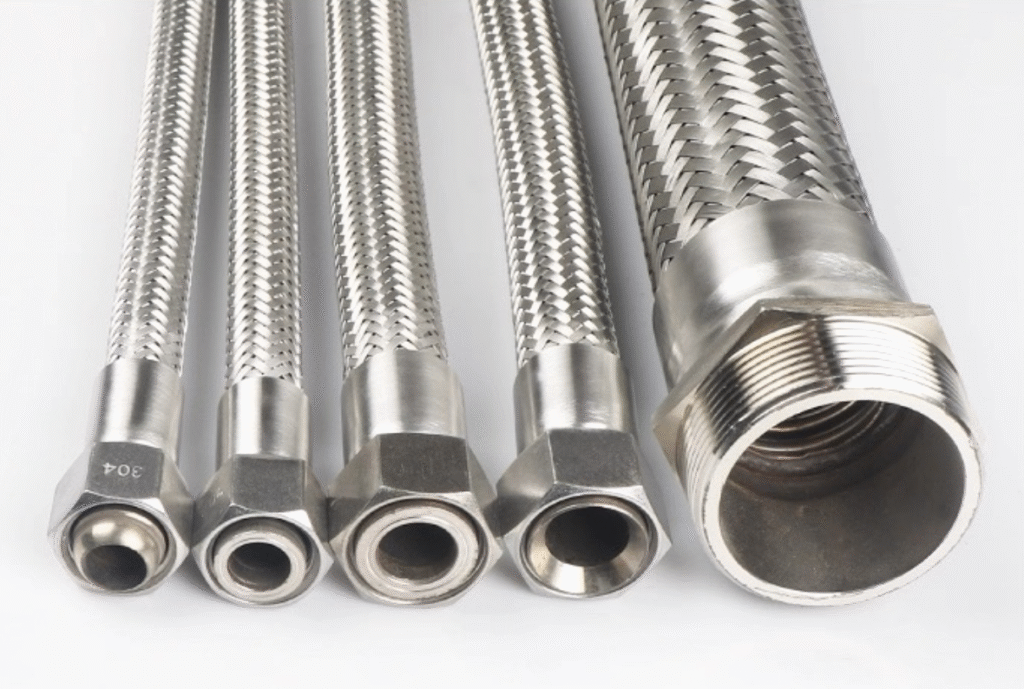

Braided Flexible Hose

Titanium Expansion Joint

Movable Bellows Compensator

Pressure Steam Braided Hose

Vacuum Spring Expansion Joint

What is the function of this mental expansion joint?

A metal expansion joint is designed to absorb movements and stresses in piping systems caused by thermal expansion, vibration, pressure fluctuations, and mechanical forces. Its main functions include:

Compensating Thermal Expansion and Contraction – Protects pipes from damage due to temperature changes.

Reducing Vibration and Noise – Minimizes vibration from pumps, compressors, and other equipment, enhancing system stability.

Accommodating Mechanical Movements – Handles axial, lateral, and angular displacements in pipelines.

Preventing Leakage and Structural Damage – Ensures the integrity of piping systems under various operating conditions.

Metal expansion joints are widely used in industries such as power plants, chemical plants, shipbuilding, and HVAC systems, providing both reliability and long service life.

What is the Difference Between Metallic and Non-Metallic Expansion Joints?

Metallic Expansion Joints are typically made from stainless steel bellows or metal hoses. They are designed to handle high pressure, high temperature, and heavy-duty mechanical stress. They provide excellent durability, can accommodate axial, lateral, and angular movements, and are widely used in power plants, shipbuilding, and chemical industries.

Non-Metallic Expansion Joints, on the other hand, are usually made from rubber, fabric, or PTFE. They are more flexible, corrosion-resistant, and ideal for low-pressure or chemical pipelines. Non-metallic joints are effective at absorbing vibration and compensating minor misalignments, but they are generally not suitable for extremely high temperatures or pressures.

Summary: Metallic joints = high temperature/pressure & mechanical strength; Non-metallic joints = flexibility, corrosion resistance & chemical applications.

What Applications Are Metal Expansion Joints Designed For?

Metal expansion joints are essential components in piping systems that experience thermal expansion, vibration, pressure changes, or mechanical movement. They are typically used to:

Absorb Thermal Expansion and Contraction – Protect pipelines from damage caused by temperature fluctuations.

Reduce Vibration and Noise – Minimize vibrations from pumps, compressors, and other equipment, improving system stability.

Accommodate Mechanical Movements – Handle axial, lateral, and angular displacements in the piping system.

Prevent Leaks and Structural Damage – Maintain pipeline integrity under various operating conditions.

Common industries that use metal expansion joints include power plants, chemical plants, shipbuilding, HVAC systems, and industrial piping networks.