Introduction by Shanghai Songjiang Shock Absorber Group Co., Ltd.

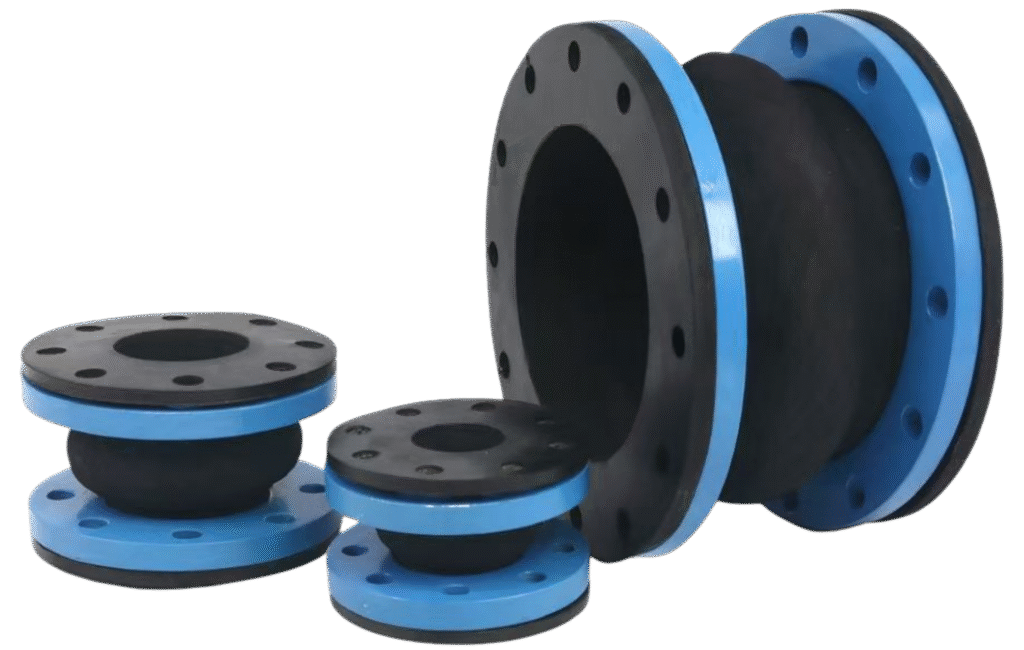

This article discusses the problem of blind flange forces generated during the installation of rubber expansion joints on water pumps and effective methods to eliminate these forces to prevent damage to the joints.

What is Blind Flange Force and Why Does It Occur?

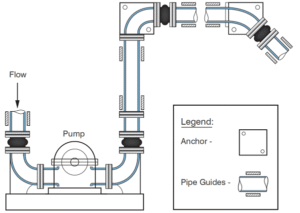

The water pump end is typically fixed on a solid foundation and can be considered a fixed point. The pipeline connected to the pump outlet may experience axial thrust due to blind flange forces generated by water pressure acting on the closed (blind) flange at the pipeline end.

Since the pipeline cannot offset this thrust easily, the axial load transfers entirely to the pump’s discharge main pipe, causing the pipe to shift or move. Excessive displacement may cause the flexible rubber expansion joint to pull out from the flange, resulting in joint damage.

Case 1: Water Pump with Horizontal (Buried) Main Pipe

When the pump outlet is connected to a straight horizontal buried main pipe (e.g., DN500 mm, supply pressure 0.55 MPa), the blind flange force generated by the outlet pressure can be very large. The soil surrounding the buried pipe restricts lateral movement, so the axial thrust cannot be relieved through pipe displacement.

Consequently, the entire thrust acts on the water pump, potentially causing:

-

Damage to pump base bolts

-

Damage to the pump foundation

Case 2: Water Pump with Vertical Outlet Piping

When the pump outlet piping is vertical, the flexible rubber expansion joint installed on the pipeline will expand and push the pipeline upward under the influence of the blind flange force caused by water pressure.

If the water pressure is too high, there is a risk that the flexible rubber joint may pull out from the flange due to this axial thrust.

Analysis of Blind Flange Force under Different Water Pressures

Blind flange force magnitude increases with:

-

Larger pipe diameters

-

Higher water pressures

Generally, for pipes with a diameter 150 mm or greater, where flexible rubber joints are installed, it is recommended to:

-

Install anti-pullout devices on the rubber joints, or

-

Use fixed pipe supports

These measures effectively eliminate the axial thrust caused by blind flange forces.

Recommended Solutions for Blind Flange Force in Pump Outlet Piping

When designing pump outlet piping systems with flexible rubber expansion joints, engineers should:

-

Analyze if the pipeline system can naturally offset or absorb the blind flange force.

-

If not, select anti-pullout type flexible rubber expansion joints to resist axial thrust.

-

Alternatively, install fixed pipe supports or brackets to prevent pipeline displacement.

These precautions will prevent damage to the rubber joints and the pump system, ensuring long-term reliable operation.

Summary

Proper handling of blind flange forces in water pump piping is critical. Selecting appropriate expansion joints with anti-pullout features or adding structural supports can effectively mitigate axial thrust, avoiding equipment damage and improving system reliability.