Vibration can significantly affect the performance of electronic systems, sensors, and UAV components. Choosing the right air damping vibration isolator ensures stable operation, longer equipment life, and better accuracy.

Why Vibration Isolation Matters

Sensitive equipment such as sensors, cameras, and communication devices require stable operating conditions. Excess vibration can lead to:

-

Reduced measurement accuracy

-

Image distortion

-

Component fatigue

-

Noise and resonance

A properly selected vibration isolator prevents these issues and improves reliability.

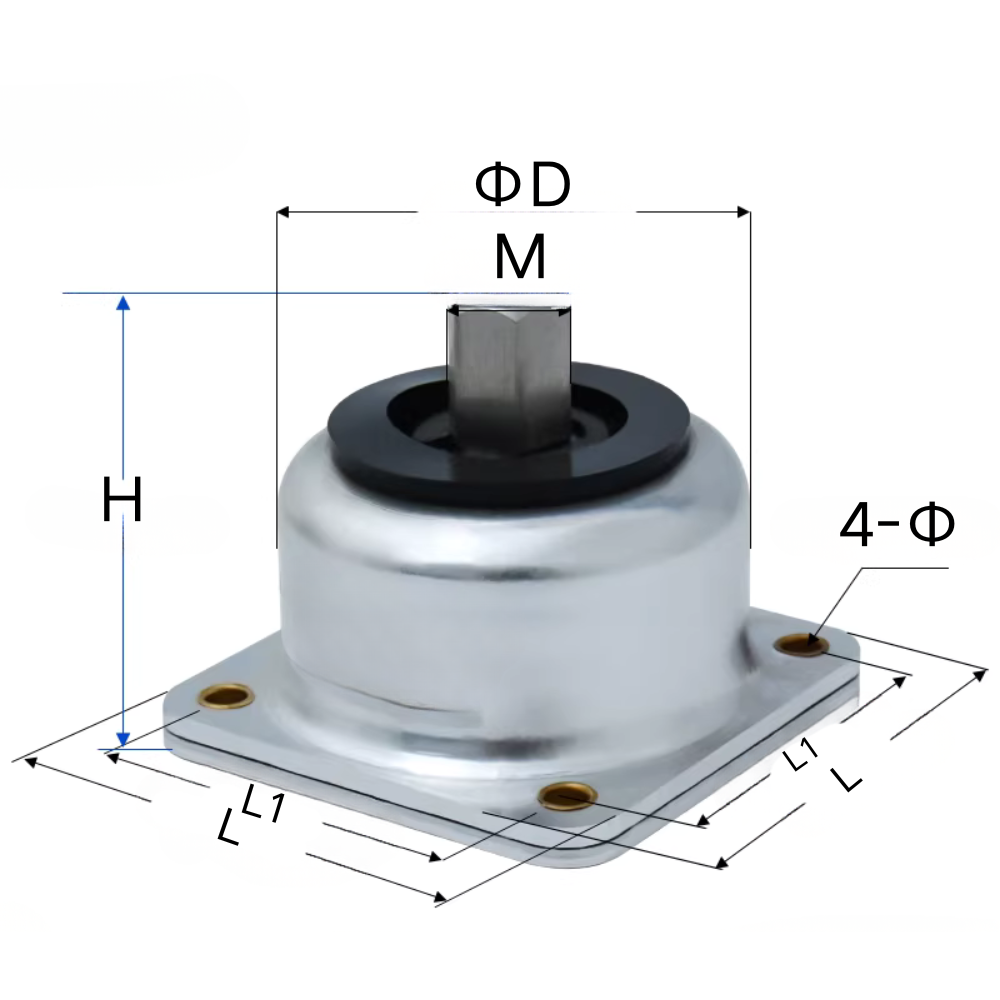

Structure of an Air Damping Vibration Isolator

An air damping vibration isolator typically consists of:

-

Aluminum housing

-

Spring support system

-

Rubber air bladder

-

Internal air damping channels

When compressed, air moves through internal passages, generating damping friction that absorbs vibration energy. This design provides both elastic support and controlled damping.

Load Range and Performance

The air damping vibration isolator with stock number 87 supports 0.4–18 kg loads.

This makes it ideal for:

-

Lightweight electronic equipment

-

UAV systems

-

Measuring instruments

-

Optical devices

The large static deflection and low natural frequency improve isolation efficiency, especially for high-frequency vibration.

Main Advantages

1. Excellent Shock Absorption

The rubber air bladder absorbs impact and vibration effectively.

2. Stable and Durable Structure

The aluminum housing ensures long service life and consistent performance.

3. Low Natural Frequency

Provides better isolation for sensitive equipment.

4. Compact and Lightweight

Perfect for onboard systems and portable equipment.

Typical Applications

Air damping vibration isolators are widely used in:

-

UAV engines and camera gimbals

-

Wireless communication devices

-

Laboratory instruments

-

Electronic control systems

-

Aerospace electronics

-

Precision testing equipment

They are particularly effective in applications requiring vertical vibration isolation and stable support.

How to Select the Right Isolator

When choosing an air damping vibration isolator, consider:

-

Equipment weight

-

Vibration frequency

-

Installation direction

-

Required damping level

-

Environmental conditions

Matching the isolator load range to the equipment weight ensures optimal performance and longer service life.

Future Trends in Vibration Isolation

With the growth of drones, electronics, and precision instruments, demand for compact and high-performance vibration isolators continues to rise. Air damping isolators provide a reliable solution for modern equipment that requires stability and protection.

Conclusion

Air damping vibration isolators combine air damping technology, spring support, and rubber elasticity to deliver excellent vibration control. They are an ideal solution for UAV systems, electronics, and precision instruments requiring stable operation and long-term reliability.