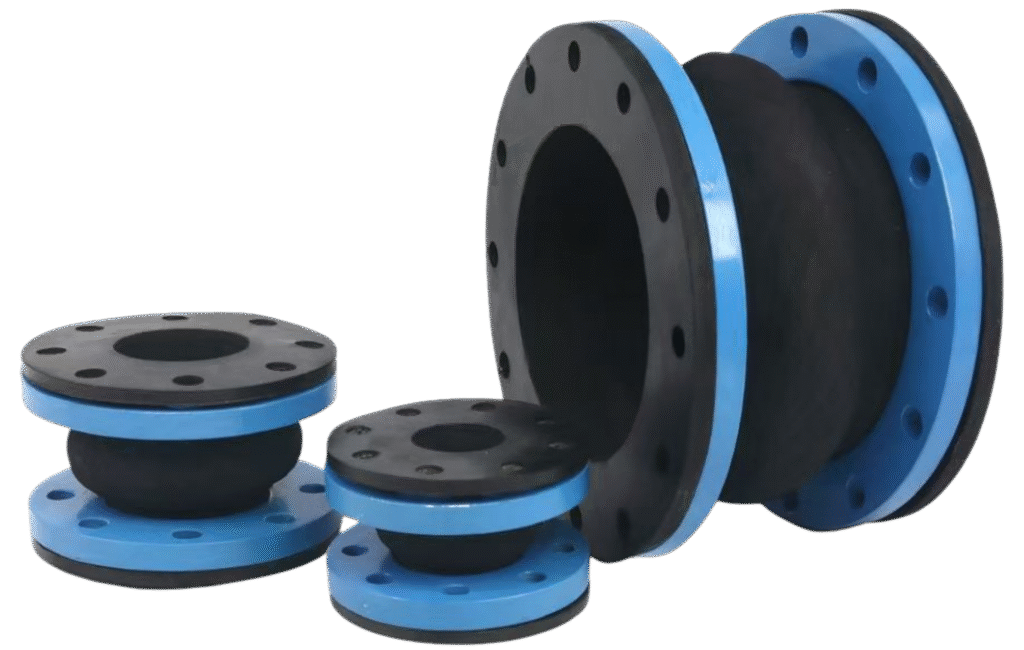

Single Sphere Rubber Expansion Joint

Home > Single Sphere Rubber Expansion Joint

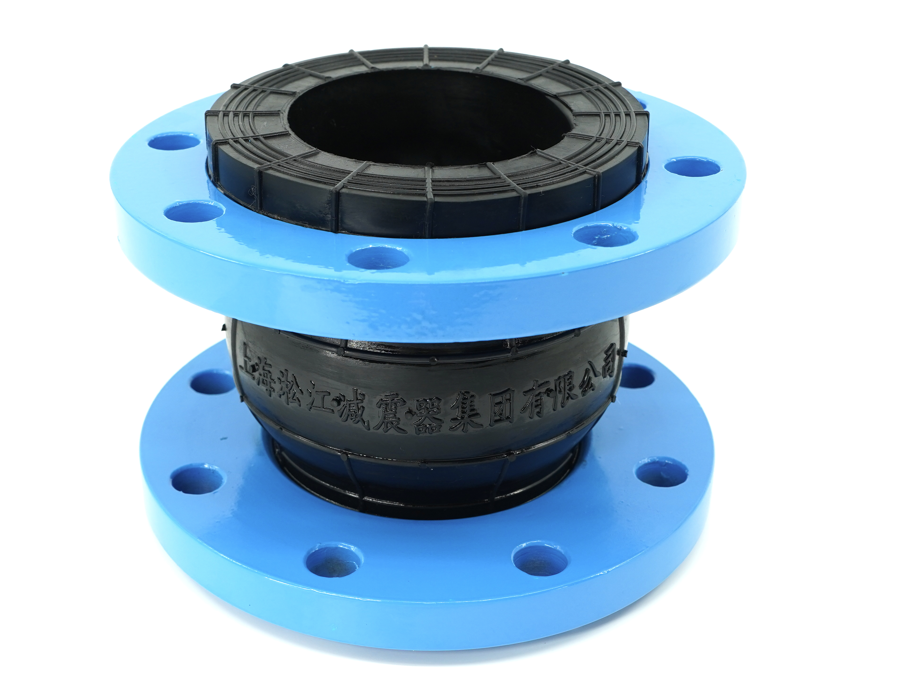

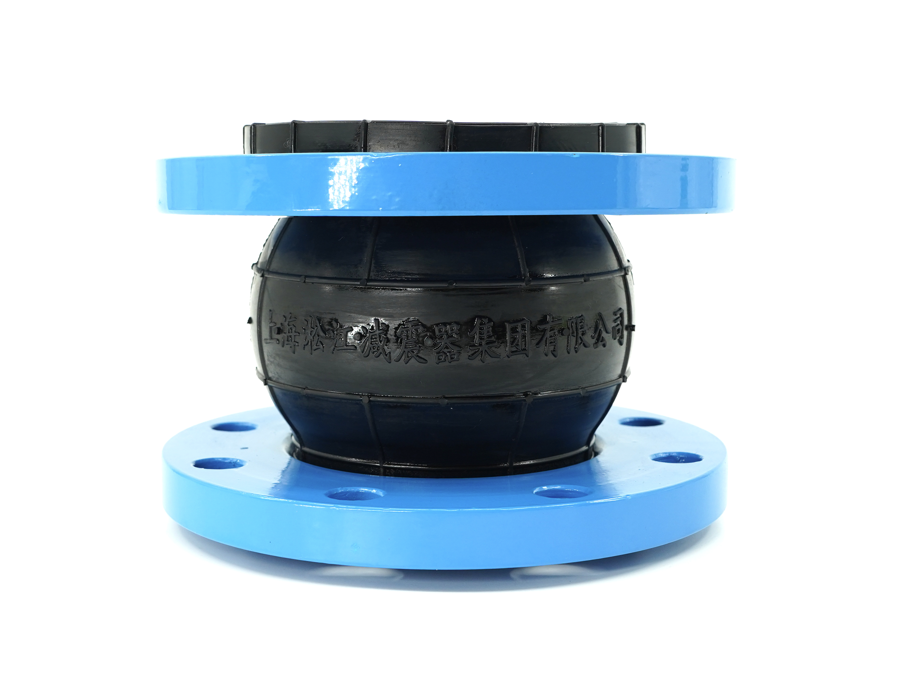

NR Expansion joints

NR Rubber (Natural Rubber) is made from high-quality natural rubber raw materials, with no recycled or reclaimed rubber added, ensuring product purity and consistent performance. It features excellent elasticity and abrasion resistance, making it suitable for various operating conditions.

This product is especially suitable for conveying ordinary water, cold and warm wastewater, as well as cooling water (excluding water containing corrosive water treatment chemicals). It is also suitable for air conveying systems at normal temperatures.

The temperature range is from -20°C to +80°C, meeting the general requirements of rubber expansion joints for industrial and municipal pipeline systems.

Our factory-produced natural rubber expansion joints are made from 100% virgin rubber with no recycled materials added. This ensures superior durability, excellent weather resistance, and a long service life even in demanding environments. Additionally, we offer full customization based on your specific application needs, including matching inner and outer rubber layers to suit various media and operating conditions.

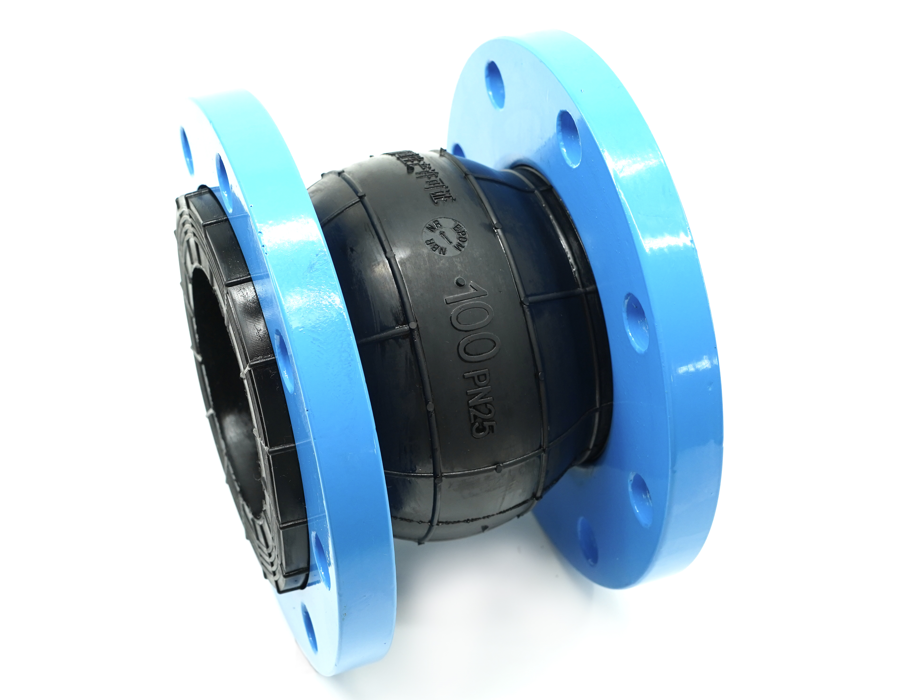

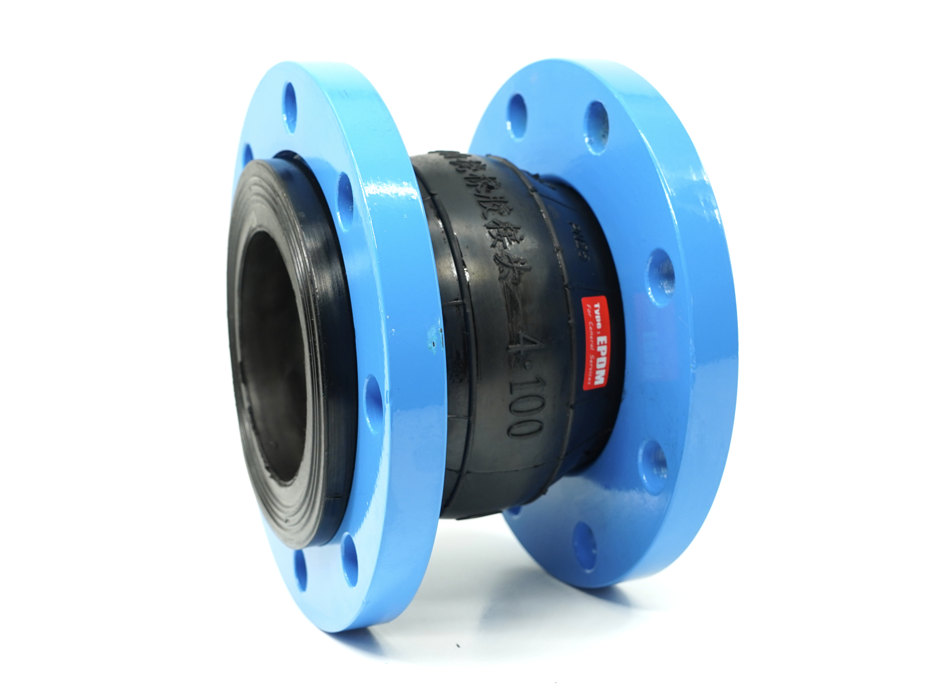

EPDM Expansion joints

Our EPDM Expansion Joints are specially designed for long-term use in heating systems, making them an ideal solution for applications involving hot heating water, cooling water, and hot air. These expansion joints are engineered to handle high-pressure environments and ensure durability over extended periods of operation.

Temperature Range:

Depending on the medium, the temperature range for the EPDM expansion joints extends from -40°C to +120°C. This wide temperature range ensures reliable performance even in challenging conditions.

Electrically Dissipative:

In addition to their excellent mechanical properties, our EPDM expansion joints are electrically dissipative, which means they are capable of effectively dispersing static charges. This feature is crucial for applications where electrical conductivity is a concern, such as in certain industrial and HVAC systems.

These expansion joints have been rigorously tested and TÜV certified, meeting international standards for safety and quality. Whether used in heating, cooling, or ventilation systems, they provide a robust, flexible solution to prevent damage from thermal expansion, contraction, and movement within pipes.

NBR Expansion joints

NBR Expansion joints is specifically engineered to meet stringent food-grade requirements and is fully compliant with international food safety standards. It is ideal for use in processing systems that handle food products, including those containing oils and fats, such as edible oils, dairy products, sauces, and other fat-based media.

Temperature Resistance:

The product is suitable for a wide temperature range, depending on the specific media. It can operate continuously from -20°C to +90°C, and can withstand short-term temperature peaks up to +100°C without compromising performance or material integrity. This makes it suitable for both cold and hot process lines in the food and beverage industry.

Electrical Insulation:

This type of food-grade rubber expansion joint is widely used in industries such as dairy processing, beverage production, edible oil refining, meat and poultry processing, and pharmaceutical-grade food systems. It is a critical component for absorbing pipeline movement, reducing vibration, and compensating for thermal expansion while maintaining food safety standards.

CR Expansion joints

CR Expansion joints is a reliable and budget-friendly choice for general-purpose applications in building services, HVAC systems, and industrial fluid handling systems. It is specially designed for use with cold and hot water, as well as media containing oil and grease, making it a versatile solution for environments where mixed fluids or utility services are present. In addition, it is suitable for use with air and compressed air systems, commonly found in pneumatic lines and mechanical installations.

Temperature Resistance:

The CR compensator is engineered to perform effectively within a temperature range of -25°C to +90°C, depending on the nature of the media. For short-term peaks, it can withstand temperatures up to +100°C without deformation or failure, making it suitable for pipelines that occasionally experience thermal fluctuations.

Electrical Insulation:

The CR model is widely used in residential plumbing, commercial HVAC systems, air compressors, cooling circuits, industrial water supply, and general-purpose fluid transfer pipelines. It helps absorb thermal expansion, reduce mechanical vibration, and minimize operational noise in both pressurized and non-pressurized systems.

FKM Expansion joints

FKM expansion joints exhibit excellent aging resistance and ozone resistance, suitable for long-term use. They effectively withstand strong acids, alkalis, organic solvents, and various chemicals, significantly extending equipment service life while reducing maintenance frequency and costs.

Temperature Resistance:

The FKM expansion joint performs reliably within a broad temperature range from -20°C to +200°C, meeting the stringent requirements of high-temperature conditions. It can withstand short-term temperatures up to +250°C, making it ideal for transporting high-temperature steam, hot oil, and other media.

Wide Application Fields:

FKM expansion joints are widely used in petroleum refining, chemical plants, pharmaceutical manufacturing, food processing, and aerospace industries. They are ideal elastic connectors for pipelines handling highly corrosive and high-temperature media. Their flexibility and durability efficiently absorb thermal expansion, vibration, and mechanical stress, ensuring the overall safety and stability of the piping system.

HYPOLLON Expansion joints

HYPOLLON rubber expansion joint is specially engineered to withstand harsh chemical environments, making it ideal for pipelines conveying aggressive acids, alkalis, and various industrial chemicals. It is also designed for use with oil-containing compressed air systems, providing reliable performance in demanding industrial applications where chemical resistance and durability are critical.

Wide Temperature Range for Versatile Applications

This expansion joint operates effectively across a broad temperature spectrum, with a standard operating range from -20°C to +90°C. It can tolerate short-term temperature spikes up to +100°C, and its maximum temperature resistance reaches +110°C. Such temperature versatility makes it suitable for a wide array of chemical processing, manufacturing, and pneumatic systems exposed to fluctuating thermal conditions.

SBR Expansion joints

SBR (Styrene-Butadiene Rubber) is a widely used synthetic rubber material known for its excellent abrasion resistance and good mechanical properties. As an economical and practical rubber, SBR plays a vital role in manufacturing tires, hoses, seals, shoe soles, and various rubber products, meeting the demands of diverse and complex working conditions.

Wide Operating Temperature Range

SBR rubber performs reliably within a temperature range of -40°C to +100°C, adapting to various climates and environmental conditions to ensure product reliability and durability.

Wide Range of Applications

Thanks to its excellent comprehensive performance, SBR rubber is widely applied in the automotive industry, construction engineering, manufacturing, and consumer goods production. Whether for abrasion-resistant tires, seals, or industrial vibration dampers, SBR offers a high cost-performance solution.

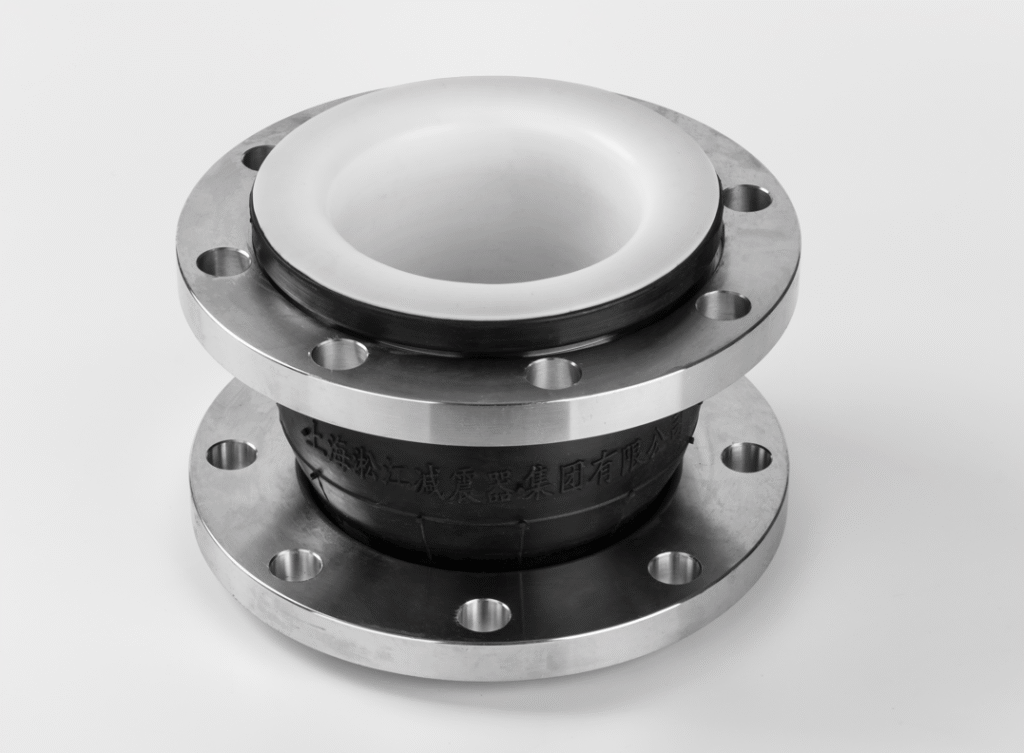

PTEF Expansion joints

PTFE rubber composite combines the exceptional chemical stability of polytetrafluoroethylene (PTFE) with the excellent elasticity of rubber, specially designed for industrial applications requiring superior corrosion resistance and mechanical flexibility. It is widely used in chemical processing, pharmaceuticals, food processing, and high-temperature, high-pressure fluid transport, meeting demanding sealing and expansion joint requirements.

Excellent High-Temperature Performance

This composite material covers a wide temperature range, typically from -50°C to +200°C, with some variants able to tolerate even higher short-term temperatures, making it suitable for high-temperature applications.

Wide Range of Applications

PTFE rubber composites are widely used in petrochemical, pharmaceutical, food industry, and environmental protection equipment fields, making them ideal for corrosion-resistant piping systems, valves, and pumps.

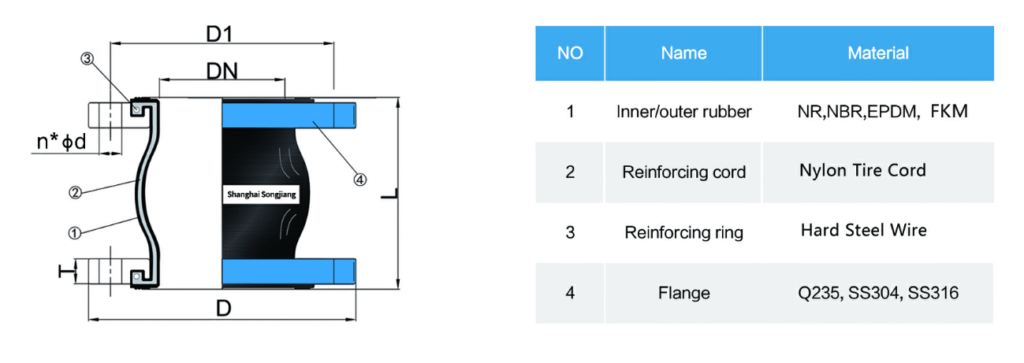

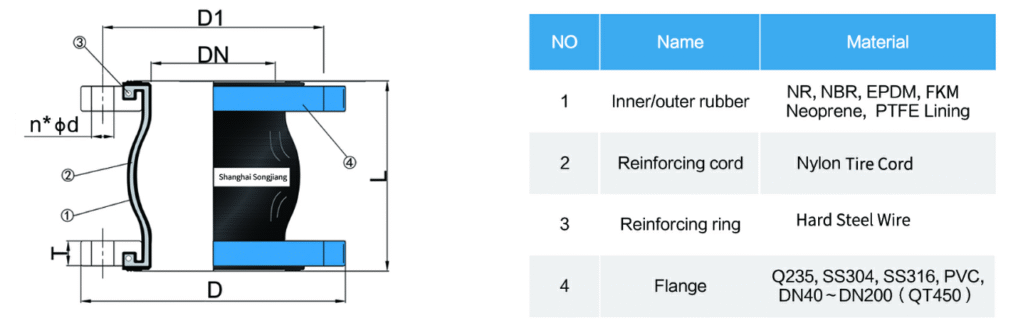

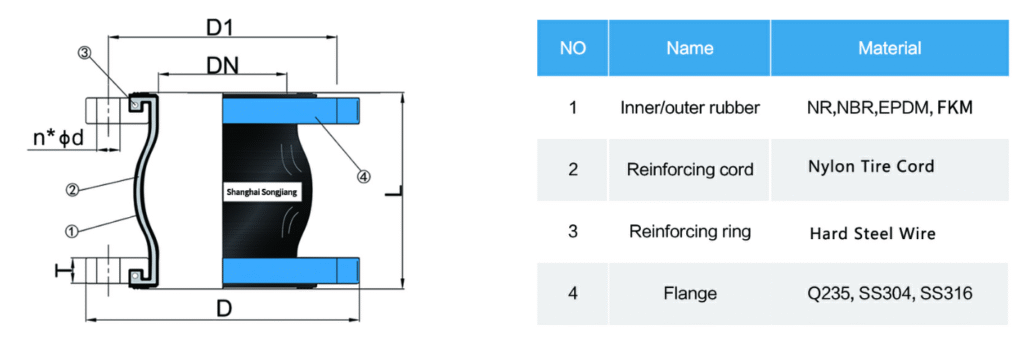

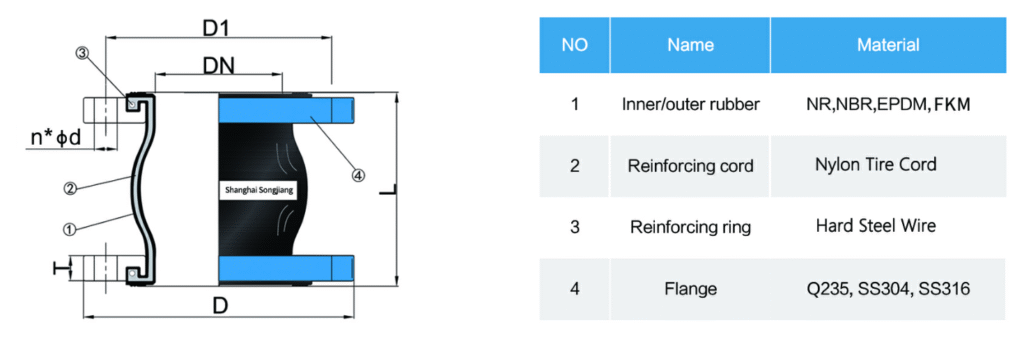

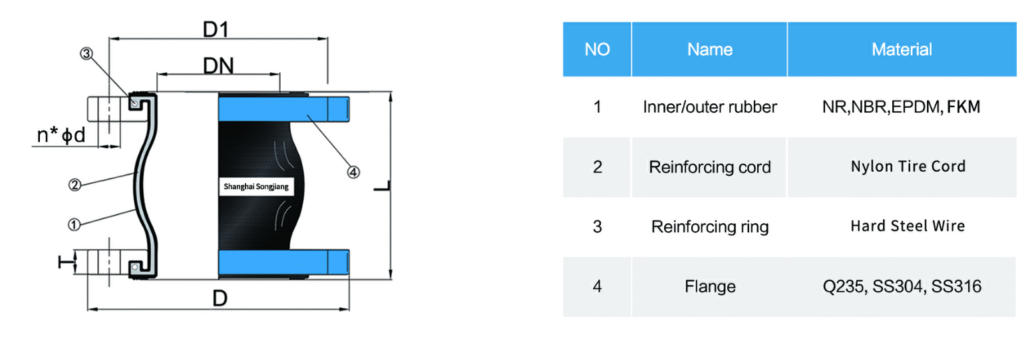

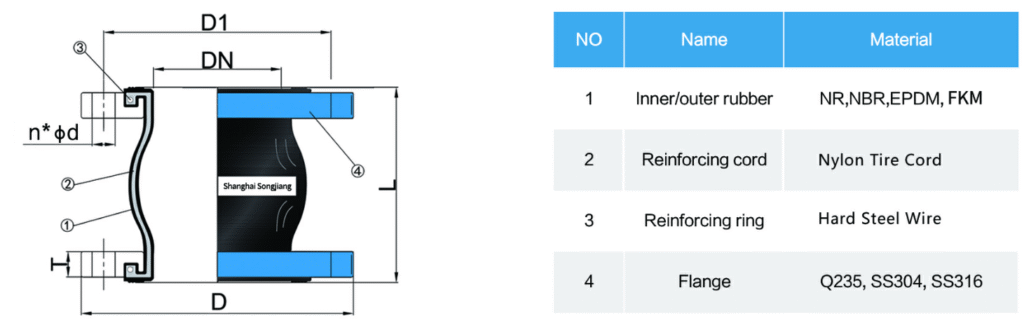

Custom Rubber Joints to Different International Standards

We offer customized rubber expansion joints designed to meet a variety of international standards. Whether you require DIN, JIS, ANSI, GOST, or any other flange standards, we can manufacture the rubber expansion joints to your exact specifications. No matter which standard flange you need, we can provide tailored solutions to meet your requirements and ensure compatibility with our rubber bellows.

Our rubber expansion joints can be designed with flanges made from a wide range of materials, including carbon steel, stainless steel, PVC, and other materials. This flexibility allows us to adapt to the specific needs of your project, whether it’s for high corrosion resistance, durability, or cost-effective solutions.

In addition to meeting international flange standards, we also ensure that the flanges are perfectly matched with our rubber bellows, which are designed to offer optimal flexibility, shock absorption, and resistance to a wide range of environmental conditions.

Whether you're working with a specific industry standard or have unique project requirements, our custom-made rubber expansion joints provide a reliable, high-quality solution for your piping and system needs.

We guarantee that every product is crafted with attention to detail, ensuring that each flange material and size is selected to match your specific operating conditions, such as pressure, temperature, and environmental factors.

Flange Standards

DIN (German Standard),

ANSI / ASME (American Standard),

JIS (Japanese Standard),

BS (British Standard),

GOST (Russian Standard),

SABS (South African Standard),

AS (Australian Standard)

No matter which flange standard you require, we can provide a precise match to ensure seamless installation.

Rubber Material (Based on Media & Environment)

EPDM – for hot water, steam, and mild chemicals. NBR – for oil, grease, and petroleum-based fluids. NR (Natural Rubber) – for abrasion and impact resistance. Neoprene – for seawater, ozone, and weather exposure. FKM (Viton) – for high temperature, acid, and chemical resistance. PTFE lining – for highly corrosive media such as strong acid and alkali.

Connection Types

Flanged Connection The most common type; compatible with various international flange standards. Clamped Connection Ideal for small diameters; allows for easy and quick installation. Threaded Connection Suitable for small pipe diameters and low-pressure systems.

Pressure Rating

Pressure Rating Application Scenarios PN10 / PN16 Common in residential buildings, HVAC systems PN25 / PN40 Industrial pipelines, chemical, energy sectors Higher Pressure (Customized) Requires reinforced frame or special structural design

Parameter Of ANSI/ASME B16.5 Class 150# Rubber Expansion Joints

| Nominal Diameter (MM) | Nominal Diameter (Inch) | Length L(mm) | Flange OD D(mm) | No. Bolts (pcs) | Bolt Hole Dia d(mm) | Flange PCD D1(mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1 | 130/150 | 110 | 4 | 16 | 79.4 | 12 | 20 | 14 | 15° | / |

| 32 | 1-1/4 | 130/150 | 120 | 4 | 16 | 88.9 | 12 | 20 | 14 | 15° | / |

| 40 | 1-1/2 | 130/150 | 130 | 4 | 16 | 98.4 | 12 | 20 | 14 | 15° | / |

| 50 | 2 | 130/150 | 150 | 4 | 18 | 120.7 | 12 | 20 | 14 | 15° | / |

| 65 | 2-1/2 | 130/150 | 180 | 4 | 18 | 139.7 | 12 | 20 | 14 | 15° | / |

| 80 | 3 | 130/150 | 190 | 4 | 18 | 152.4 | 12 | 20 | 14 | 15° | / |

| 100 | 4 | 130/150 | 230 | 8 | 18 | 190.5 | 12 | 20 | 14 | 15° | / |

| 125 | 5 | 130/150 | 255 | 8 | 22 | 215.9 | 12 | 20 | 14 | 15° | / |

| 150 | 6 | 130/150 | 280 | 8 | 22 | 241.3 | 12 | 20 | 14 | 15° | / |

| 200 | 8 | 130/150/200 | 345 | 8 | 22 | 298.5 | 12 | 20 | 14 | 15° | 3 |

| 250 | 10 | 130/150/200 | 405 | 12 | 26 | 362 | 12 | 20 | 14 | 15° | 3 |

| 300 | 12 | 130/200 | 485 | 12 | 26 | 431.8 | 16 | 25 | 22 | 15° | 3 |

| 350 | 14 | 200 | 535 | 12 | 30 | 476.3 | 16 | 25 | 22 | 15° | 4 |

| 400 | 16 | 200 | 600 | 16 | 30 | 539.8 | 16 | 25 | 22 | 15° | 4 |

| 450 | 18 | 200 | 635 | 16 | 33 | 577.9 | 16 | 25 | 22 | 15° | 4 |

| 500 | 20 | 200 | 700 | 20 | 33 | 635 | 16 | 25 | 22 | 15° | 5 |

Parameter Of KXT Type Flexible Rubber Expansion Joints

| Nominal Diameter (MM) | Nominal Diameter (Inch) | Length L(mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|

| 25 | 1 | 95 | 6 | 9 | 9 | 15° | / |

| 32 | 1–1/4 | 95 | 6 | 9 | 9 | 15° | / |

| 40 | 1–1/2 | 95 | 6 | 10 | 9 | 15° | / |

| 50 | 2 | 105 | 7 | 10 | 10 | 15° | / |

| 65 | 2–1/2 | 115 | 7 | 13 | 11 | 15° | / |

| 80 | 3 | 135 | 8 | 15 | 12 | 15° | / |

| 100 | 4 | 150 | 10 | 19 | 13 | 15° | / |

| 125 | 5 | 165 | 12 | 19 | 13 | 15° | / |

| 150 | 6 | 180 | 12 | 20 | 14 | 15° | / |

| 200 | 8 | 210 | 16 | 25 | 22 | 10° | / |

| 250 | 10 | 230 | 16 | 25 | 22 | 10° | / |

| 300 | 12 | 245 | 16 | 25 | 22 | 10° | / |

| 350 | 14 | 255 | 16 | 25 | 22 | 10° | 4 |

| 400 | 16 | 255 | 16 | 25 | 22 | 10° | 4 |

| 450 | 18 | 255 | 16 | 25 | 22 | 5° | 4 |

| 500 | 20 | 255 | 16 | 25 | 22 | 5° | 5 |

| 600 | 24 | 260 | 16 | 25 | 22 | 5° | 5 |

| 700 | 28 | 260 | 16 | 25 | 22 | 5° | 5 |

| 800 | 32 | 260 | 16 | 25 | 22 | 5° | 5 |

| 900 | 36 | 260 | 16 | 25 | 22 | 5° | 6 |

| 1000 | 40 | 260 | 16 | 25 | 22 | 5° | 6 |

| 1200 | 48 | 260 | 16 | 25 | 22 | 5° | 6 |

Parameter Of EN 1092-1 European Standard Rubber Expansion Joints

| Nominal Diameter (MM) | Nominal Diameter (Inch) | Length L(mm) | Flange OD D(mm) | No. Bolts (pcs) | Bolt Hole Dia d(mm) | Flange PCD D1(mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1 | 95 | 115 | 4 | 14 | 85 | 6 | 9 | 9 | 15° | / |

| 32 | 1–1/4 | 95 | 140 | 4 | 18 | 100 | 6 | 9 | 9 | 15° | / |

| 40 | 1–1/2 | 95 | 150 | 4 | 18 | 110 | 6 | 10 | 9 | 15° | / |

| 50 | 2 | 105 | 165 | 4 | 18 | 125 | 7 | 10 | 10 | 15° | / |

| 65 | 2–1/2 | 115 | 185 | 4 | 18 | 145 | 7 | 13 | 11 | 15° | / |

| 80 | 3 | 135 | 200 | 8 | 18 | 160 | 8 | 15 | 12 | 15° | / |

| 100 | 4 | 150 | 220 | 8 | 18 | 180 | 10 | 19 | 13 | 15° | / |

| 125 | 5 | 165 | 250 | 8 | 18 | 210 | 12 | 19 | 13 | 15° | / |

| 150 | 6 | 180 | 285 | 8 | 22 | 240 | 12 | 20 | 14 | 15° | / |

| 200 | 8 | 210 | 340 | 8 | 22 | 295 | 16 | 25 | 22 | 10° | / |

| 250 | 10 | 230 | 395 | 12 | 22 | 350 | 16 | 25 | 22 | 10° | / |

| 300 | 12 | 245 | 445 | 12 | 22 | 400 | 16 | 25 | 22 | 10° | / |

| 350 | 14 | 255 | 505 | 16 | 22 | 460 | 16 | 25 | 22 | 10° | 4 |

| 400 | 16 | 255 | 565 | 16 | 26 | 515 | 16 | 25 | 22 | 10° | 4 |

| 450 | 18 | 255 | 615 | 20 | 26 | 565 | 16 | 25 | 22 | 5° | 4 |

| 500 | 20 | 255 | 670 | 20 | 26 | 620 | 16 | 25 | 22 | 5° | 5 |

| 600 | 24 | 260 | 780 | 20 | 30 | 725 | 16 | 25 | 22 | 5° | 5 |

Parameter Of Japanese standard JlS 5K/10K Rubber Expansion Joint:

| Nominal Diameter (mm) | Nominal Diameter (inch) | Length L (mm) | Flange OD 5K D(mm) | Flange OD 10K D(mm) | No. of Bolts 5K n(pcs) | No. of Bolts 10K n(pcs) | Bolt Hole Diameter 5K d(mm) | Bolt Hole Diameter 10K d(mm) | Flange PCD 5K D1(mm) | Flange PCD 10K D1(mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25A | 1 | 95 | 95 | 125 | 4 | 4 | 12 | 19 | 75 | 90 | 6 | 9 | 9 | 15° | / |

| 32A | 1-1/4 | 95 | 115 | 135 | 4 | 4 | 15 | 19 | 90 | 100 | 6 | 9 | 9 | 15° | / |

| 40A | 1-1/2 | 95 | 120 | 140 | 4 | 4 | 15 | 19 | 95 | 105 | 6 | 10 | 9 | 15° | / |

| 50A | 2 | 105 | 130 | 155 | 4 | 4 | 15 | 19 | 105 | 120 | 7 | 10 | 10 | 15° | / |

| 65A | 2-1/2 | 115 | 155 | 175 | 4 | 4 | 15 | 19 | 130 | 140 | 7 | 13 | 11 | 15° | / |

| 80A | 3 | 135 | 180 | 185 | 8 | 8 | 19 | 19 | 145 | 150 | 8 | 15 | 12 | 15° | / |

| 100A | 4 | 150 | 200 | 210 | 8 | 8 | 19 | 19 | 165 | 175 | 10 | 19 | 13 | 15° | / |

| 125A | 5 | 165 | 235 | 250 | 8 | 8 | 19 | 23 | 200 | 210 | 12 | 19 | 13 | 15° | / |

| 150A | 6 | 180 | 265 | 280 | 8 | 8 | 19 | 23 | 230 | 240 | 12 | 20 | 14 | 15° | / |

| 200A | 8 | 210 | 320 | 330 | 12 | 12 | 23 | 23 | 280 | 290 | 16 | 25 | 22 | 10° | / |

| 250A | 10 | 230 | 385 | 400 | 12 | 12 | 23 | 25 | 345 | 355 | 16 | 25 | 22 | 10° | / |

| 300A | 12 | 245 | 430 | 445 | 16 | 16 | 23 | 25 | 390 | 400 | 16 | 25 | 22 | 10° | / |

| 350A | 14 | 255 | 480 | 490 | 16 | 16 | 25 | 25 | 435 | 445 | 16 | 25 | 22 | 10° | 4 |

| 400A | 16 | 255 | 540 | 560 | 16 | 16 | 25 | 27 | 495 | 510 | 16 | 25 | 22 | 10° | 4 |

| 450A | 18 | 255 | 605 | 620 | 16 | 20 | 25 | 27 | 555 | 565 | 16 | 25 | 22 | 5° | 4 |

| 500A | 20 | 255 | 655 | 675 | 20 | 20 | 25 | 27 | 605 | 620 | 16 | 25 | 22 | 5° | 5 |

| 600A | 24 | 260 | 770 | 795 | 20 | 20 | 25 | 33 | 715 | 730 | 16 | 25 | 22 | 5° | 5 |

Parameter Of AS 4504 British Standard Rubber Expansion Joints

| Nominal Diameter (mm) | Nominal Diameter (inch) | Length L (mm) | Flange OD D (mm) | No. Bolts n(pcs) | Bolt Hole Diameter d (mm) | Flange PCD D1 (mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1 | 95 | 115 | 4 | 14 | 85 | 6 | 9 | 9 | 15° | / |

| 32 | 1-1/4 | 95 | 140 | 4 | 18 | 100 | 6 | 9 | 9 | 15° | / |

| 40 | 1-1/2 | 95 | 150 | 4 | 18 | 110 | 6 | 10 | 9 | 15° | / |

| 50 | 2 | 105 | 165 | 4 | 18 | 125 | 7 | 10 | 10 | 15° | / |

| 65 | 2-1/2 | 115 | 185 | 4 | 18 | 145 | 7 | 13 | 11 | 15° | / |

| 80 | 3 | 135 | 200 | 8 | 18 | 160 | 8 | 15 | 12 | 15° | / |

| 100 | 4 | 150 | 220 | 8 | 18 | 180 | 10 | 19 | 13 | 15° | / |

| 125 | 5 | 165 | 250 | 8 | 18 | 210 | 12 | 19 | 13 | 15° | / |

| 150 | 6 | 180 | 285 | 8 | 22 | 240 | 12 | 20 | 14 | 15° | / |

| 200 | 8 | 210 | 340 | 8 | 22 | 295 | 16 | 25 | 22 | 10° | / |

| 250 | 10 | 230 | 395 | 12 | 22 | 350 | 16 | 25 | 22 | 10° | / |

| 300 | 12 | 245 | 445 | 12 | 22 | 400 | 16 | 25 | 22 | 10° | / |

| 350 | 14 | 255 | 505 | 16 | 22 | 460 | 16 | 25 | 22 | 10° | 4 |

| 400 | 16 | 255 | 565 | 16 | 26 | 515 | 16 | 25 | 22 | 10° | 4 |

| 450 | 18 | 255 | 615 | 20 | 26 | 565 | 16 | 25 | 22 | 5° | 4 |

| 500 | 20 | 255 | 670 | 20 | 26 | 620 | 16 | 25 | 22 | 5° | 5 |

| 600 | 24 | 260 | 780 | 20 | 30 | 725 | 16 | 25 | 22 | 5° | 5 |

Parameter Of GOST 12820-80 Russian Standard Rubber Expansion Joints

| Nominal Diameter (mm) | Nominal Diameter (inch) | Length L (mm) | Flange OD D (mm) | No.Bolts n(pcs) | Bolt Hole Diameter d (mm) | Flange PCD D1 (mm) | Axial Elongation (mm) | Axial Compression (mm) | Lateral (mm) | Angular (°) | Control Tie Rods (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1 | 95 | 115 | 4 | 14 | 85 | 6 | 9 | 9 | 15° | / |

| 32 | 1-1/4 | 95 | 140 | 4 | 18 | 100 | 6 | 9 | 9 | 15° | / |

| 40 | 1-1/2 | 95 | 150 | 4 | 18 | 110 | 6 | 10 | 9 | 15° | / |

| 50 | 2 | 105 | 165 | 4 | 18 | 125 | 7 | 10 | 10 | 15° | / |

| 65 | 2-1/2 | 115 | 185 | 4 | 18 | 145 | 7 | 13 | 11 | 15° | / |

| 80 | 3 | 135 | 200 | 8 | 18 | 160 | 8 | 15 | 12 | 15° | / |

| 100 | 4 | 150 | 220 | 8 | 18 | 180 | 10 | 19 | 13 | 15° | / |

| 125 | 5 | 165 | 250 | 8 | 18 | 210 | 12 | 19 | 13 | 15° | / |

| 150 | 6 | 180 | 285 | 8 | 22 | 240 | 12 | 20 | 14 | 15° | / |

| 200 | 8 | 210 | 340 | 8 | 22 | 295 | 16 | 25 | 22 | 10° | / |

| 250 | 10 | 230 | 395 | 12 | 22 | 350 | 16 | 25 | 22 | 10° | / |

| 300 | 12 | 245 | 445 | 12 | 22 | 400 | 16 | 25 | 22 | 10° | / |

| 350 | 14 | 255 | 505 | 16 | 22 | 460 | 16 | 25 | 22 | 10° | 4 |

| 400 | 16 | 255 | 565 | 16 | 26 | 515 | 16 | 25 | 22 | 10° | 4 |

| 450 | 18 | 255 | 615 | 20 | 26 | 565 | 16 | 25 | 22 | 5° | 4 |

| 500 | 20 | 255 | 670 | 20 | 26 | 620 | 16 | 25 | 22 | 5° | 5 |

| 600 | 24 | 260 | 780 | 20 | 30 | 725 | 16 | 25 | 22 | 5° | 5 |

New Business Ideas. Exploring new solutions for vibration control and pipeline flexibility.

Custom Design Service

We provide fully customized solutions for rubber expansion joints and vibration isolators to suit special working conditions. This includes custom sizes, materials, flange standards, and structural designs to match your unique system requirements.

READ MORE

Marine & Offshore Applications

We are expanding into the marine and offshore sectors with corrosion-resistant products such as stainless steel flanged joints, FKM-lined rubber joints, and specially designed components that withstand saltwater and harsh marine environments.

READ MORE

High-Temperature & Chemical Resistant Solutions

To serve industries like petrochemical, power generation, and chemical processing, we offer rubber joints made with advanced materials for high temperature and aggressive chemical media, ensuring long-term reliability and safety.

READ MORE