RUBBER EXPANSION JOINTS

PRODUCT > RUBBER EXPANSION JOINTS

What is A Rubber Expansion Joint?

A rubber expansion joint is a flexible connector installed in piping systems, typically composed of a rubber body, reinforcement layers (such as fabric or steel wire), and flanges or connectors. Its primary function is to absorb axial, lateral, and angular displacements caused by thermal expansion and contraction, mechanical vibration, equipment operation, or foundation settlement. This type of expansion joint offers excellent elasticity, sealing performance, and corrosion resistance. It effectively reduces noise transmission, extends the service life of equipment, and compensates for installation misalignment between pipes. Rubber expansion joints are widely used in water supply, HVAC, chemical, power generation, metallurgy, marine, and construction industries. Depending on the application environment, different rubber materials—such as natural rubber, nitrile rubber, fluororubber, and EPDM (ethylene propylene diene monomer) rubber—can be selected to accommodate various media and operating temperatures.

Our project case

For the cooling tower project, install DN300 and DN400 PN16 weather-resistant rubber expansion joints.

Rubber Expansion Joint Classifications

Rubber expansion joints can be classified based on temperature resistance (low, medium, and high temperature), structural form (single sphere, double sphere, or multiple convolutions), shape (circular or customized), and connection method (flanged or threaded). Each type is designed to meet specific working conditions requiring excellent sealing, corrosion resistance, and flexibility. They are widely used in piping systems that transport high-temperature, acidic, alkaline, or oil-based corrosive media.

Large Flange Rubber Expansion Joint

ANSI Standard Fire-resistant Rubber Expansion Joint

Reinforced Rubber Expansion Joint

Threaded Rubber Expansion Joint

Hose Clamp Rubber Expansion Joint

EPDM Rubber DIN Standard Expansion Joint

Rubber Expansion Joint for Continuous Casting System

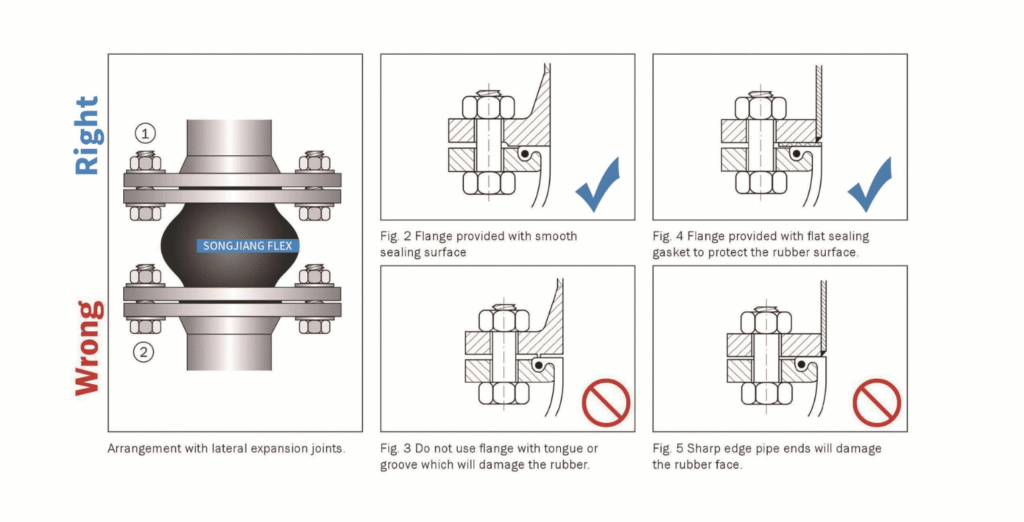

How to Choose Special Flanges for Flexible Rubber Expansion Joints?

Flexible rubber joints should be matched with special flanges for butterfly valves to ensure a reliable, durable, and safe connection.

To ensure a proper seal, durability, and safe operation, using a properly matched flange is essential.

When using a flat welding flange on the pipeline, it is recommended to choose flanges specifically designed for wafer-type butterfly valves.

a) The inner diameter at the pipe connection must match the inner diameter of the rubber joint.

b) The flange surface in contact with the rubber joint must be smooth and flat to ensure maximum sealing performance.If the rubber joint does not fit tightly against the flange face, issues such as noise, insufficient pressure resistance, or water leakage may arise.

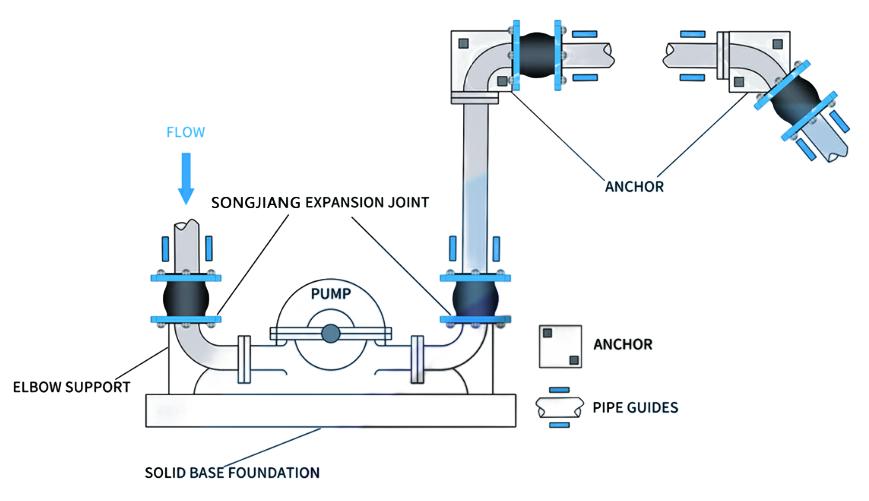

What Should Be Paid Attention to When Installing Rubber Expansion Joints?

When installing flexible rubber joints on water pipelines, the design standards must be strictly followed to prevent excessive elongation of the rubber joint, ensuring its normal service life and performance.

It is recommended to install the flexible rubber joint immediately after the fixed supports are installed to avoid displacement or stress concentration caused by unsupported pipelines.

After installation, pipeline guide supports should be placed behind the rubber joint on the pipeline to ensure stability and prevent displacement or vibration, protecting the rubber joint from damage.

Proper installation procedures and support measures are essential to guarantee the performance and extend the service life of rubber expansion joints.

What are the Functions of Different of Rubber Expansion Joints?

The functions of different types of rubber expansion joints vary based on their design and application requirements. Here are some common types and their functions:

Single Sphere Rubber Expansion Joint

Function: Absorbs axial, lateral, and angular movements. Its simple structure is suitable for pipelines with limited space and small displacement requirements.

Typical Applications: HVAC water systems, pump-to-pipe connections, residential water supply and drainage.Double Sphere Rubber Expansion Joint

Function: Offers greater expansion and displacement capacity than single sphere joints, with better vibration and noise reduction performance. Suitable for pipelines with larger movements.

Typical Applications: Large pump systems, long-distance pipelines, connections on equipment with frequent vibrations.Reducer (Concentric) Rubber Expansion Joint

Function: Connects pipes of different diameters, compensates for installation stresses caused by diameter changes, and provides flexibility.

Typical Applications: Pipeline renovations, pump outlet diameter changes, water treatment equipment connections.High-Temperature Resistant Rubber Expansion Joint

Function: Made from materials such as EPDM or Viton, these joints withstand high temperatures, suitable for hot water or steam pipelines.

Typical Applications: Boilers, HVAC steam systems, chemical heating pipelines.Acid and Alkali Resistant Rubber Expansion Joint

Function: Lined with special rubber like Viton or Butyl, these joints resist corrosion from aggressive fluids.

Typical Applications: Chemical plants, pharmaceutical plants, acid/alkali conveying pipelines.Oil Resistant Rubber Expansion Joint

Function: Made from nitrile rubber (NBR), offering excellent oil resistance for pipelines transporting oils.

Typical Applications: Petroleum, diesel, and lubricating oil transportation systems.Detachable (Flanged) Rubber Expansion Joint

Function: Equipped with loose flanges at both ends for easy installation and maintenance, allowing replacement without dismantling entire pipeline sections.

Typical Applications: Equipment with frequent maintenance, pipeline sections requiring easy disassembly.

How Long do Rubber Expansion Joints Last?

Rubber expansion joints play a vital role in piping systems by absorbing movements in multiple directions—such as compression, extension, and lateral shifts. They also help reduce vibrations and minimize noise transmission within the pipeline. These joints are commonly installed near pumps, boilers, tanks, cooling towers, heat exchangers, and along long pipe runs to ensure the system’s flexibility and to relieve stress.

The lifespan of rubber expansion joints varies widely depending on factors like operating conditions and the environment in which they are used. Typically, a rubber expansion joint lasts between 7 and 10 years. However, in harsher conditions—such as exposure to high temperatures, elevated pressures, abrasive or corrosive substances, or frequent movement—their service life may be reduced to only a few months. Conversely, with optimal conditions and proper maintenance, some rubber expansion joints can remain functional for over 25 years.

Several factors influence the durability of rubber expansion joints, including the quality of materials, the degree of mechanical stress, and environmental exposure. Because of these variables, it’s challenging to predict the exact time for replacement or failure. Unexpected failure of expansion joints can cause leaks, equipment downtime, and costly disruptions.

To minimize the risk of failure, regular inspection and condition monitoring of rubber expansion joints are essential. Conducting periodic surveys helps identify wear and potential problems early, allowing timely maintenance or replacement. This proactive approach reduces unexpected shutdowns and enhances plant safety and productivity.

At our factory, we manufacture high-quality rubber expansion joints that surpass many market alternatives in durability and performance. We also offer customization tailored to specific customer requirements and operating environments, ensuring each product delivers long-lasting, reliable service.