PTFE-Lined Rubber Expansion Joint

Home > PTFE-Lined Rubber Expansion Joint

PTFE-Lined Rubber Expansion Joint

The PTFE-lined rubber expansion joint features a layer of PTFE lining inside the rubber bellows, combining excellent corrosion resistance and high-temperature performance. It is ideal for conveying strong acids, alkalis, and high-temperature media. With superior sealing and extended service life, it is the perfect piping solution for chemical, pharmaceutical, food, and other industries.

PTFE Lined Rubber Expansion Joint – The Ultimate Chemical Resistant Solution

Our PTFE lined rubber expansion joints are engineered to provide maximum corrosion resistance and flexibility in industrial pipeline systems. Designed for use with corrosive media, this high-performance chemical resistant expansion joint is ideal for demanding applications in chemical, petrochemical, pharmaceutical, and wastewater treatment industries.

Key Features:

PTFE Lining: Offers exceptional resistance to acids, alkalis, and aggressive chemicals, making it perfect for acid resistant expansion bellow applications.

Flexible Rubber Outer Body: Excellent elasticity absorbs pipeline vibration, thermal expansion, and misalignment.

Durability: Made from high-quality materials for long-term service life in harsh industrial environments.

Versatile Flange Connections: Compatible with stainless steel flanges and standard pipeline systems.

Benefits:

Effectively isolates pipeline vibration and reduces mechanical stress.

Prevents corrosion-related failures, reducing maintenance and downtime.

Enhances the safety and reliability of your industrial piping system.

Suitable for new installations and retrofitting of existing pipelines.

Applications:

This flexible rubber joint for corrosive media is widely used in:

Chemical processing plants

Oil and gas facilities

Pharmaceutical manufacturing

Power plants and water treatment systems

Whether you're designing a new system or upgrading an existing one, our industrial rubber compensator with PTFE lining is a cost-effective and high-performance solution.

Contact us today to learn more about our PTFE expansion joints or to get technical support for your project.

Ordering Information

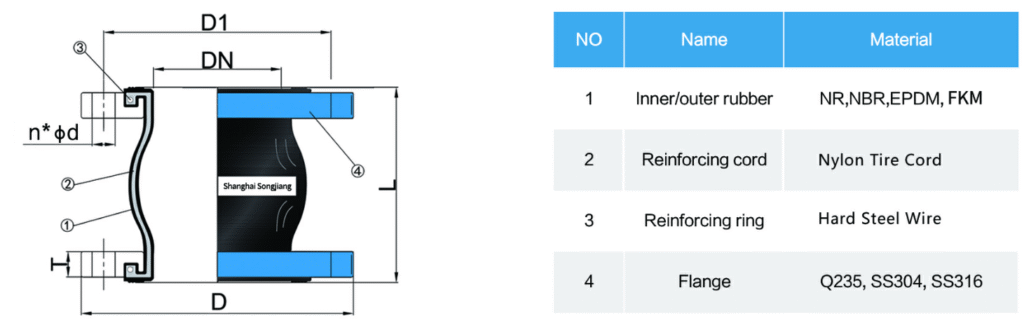

When placing an order for Full Faced Molded Rubber Expansion Joints, please kindly confirm the following details to ensure correct product selection:

Nominal diameter (in mm or inch)

Working pressure and temperature of the system

Medium type (e.g., water, air, oil, chemicals)

Rubber material requirement (e.g., EPDM for hot water, NBR for oil, Neoprene for general use)

Flange material (e.g., carbon steel, stainless steel, galvanized)

Flange drilling standard (e.g., DIN, ANSI, JIS, BS, or customized according to your drawing)

Quantity needed and expected delivery time

Since the product is mold-formed, the dimensions are fixed. However, we can fully customize the rubber compound and flange specifications according to your application requirements.

For special working conditions or installation limitations, please feel free to contact our technical team for assistance.Why Are More and More Projects Choosing PTFE Lined Rubber Expansion Joints? Here’s the Answer!

In industries like chemical processing, pharmaceuticals, food production, and paper manufacturing, piping systems often face highly corrosive environments. How can you ensure reliable sealing, flexibility, and long-term performance? The answer many customers agree on is choosing PTFE lined rubber expansion joints.

These joints feature a 1–2 mm thick PTFE lining inside the rubber body, effectively isolating corrosive media from direct contact with the rubber. This greatly enhances chemical resistance and extends service life. The lining thickness may vary slightly by model, and if you have special corrosion-resistance requirements, we offer customized solutions—feel free to contact us anytime to discuss your needs!

Key Benefits:

✅ Resistant to highly corrosive media

✅ High temperature and pressure tolerance

✅ Excellent aging and wear resistance

✅ Customization available for special requirements

PTFE Lined Rubber Expansion Joint – Standard Dimensions

| Nominal Diameter (DN) | Inch Size (“) | Length (L) mm | Flange Outer Diameter (OD) mm | Bolt Circle Diameter (PCD) mm | Hole Diameter (d) mm | Number of Bolts |

|---|---|---|---|---|---|---|

| DN32 | 1¼” | 95 | 135 | 100 | 18 | 4 |

| DN40 | 1½” | 95 | 145 | 110 | 18 | 4 |

| DN50 | 2″ | 105 | 160 | 125 | 18 | 4 |

| DN65 | 2½” | 115 | 180 | 145 | 18 | 4 |

| DN80 | 3″ | 135 | 195 | 160 | 18 | 8 |

| DN100 | 4″ | 150 | 215 | 180 | 18 | 8 |

| DN125 | 5″ | 165 | 245 | 210 | 18 | 8 |

| DN150 | 6″ | 180 | 280 | 240 | 22 | 8 |

| DN200 | 8″ | 200 | 335 | 295 | 22 | 8 |

| DN250 | 10″ | 225 | 405 | 355 | 26 | 12 |

| DN300 | 12″ | 250 | 460 | 410 | 26 | 12 |

| DN350 | 14″ | 250 | 520 | 470 | 26 | 16 |

| DN400 | 16″ | 250 | 580 | 525 | 30 | 16 |

| DN450 | 18″ | 250 | 640 | 585 | 30 | 20 |

| DN500 | 20″ | 250 | 715 | 650 | 33 | 20 |

| DN600 | 24″ | 260 | 840 | 770 | 36 | 20 |

| DN700 | 28″ | 280 | 910 | 840 | 36 | 24 |

| DN800 | 32″ | 300 | 1020 | 950 | 39 | 24 |

| DN900 | 36″ | 320 | 1120 | 1050 | 39 | 28 |

| DN1000 | 40″ | 340 | 1255 | 1170 | 42 | 28 |

| DN1200 | 48″ | 360 | 1485 | 1390 | 48 | 32 |

Note: The PTFE lining is typically 1–2 mm thick, but the thickness may vary depending on the model. If you have specific requirements for thickness, material, or chemical compatibility, feel free to contact us for customized solutions.