Lined Expansion Joint

Home > Lined Expansion Joint

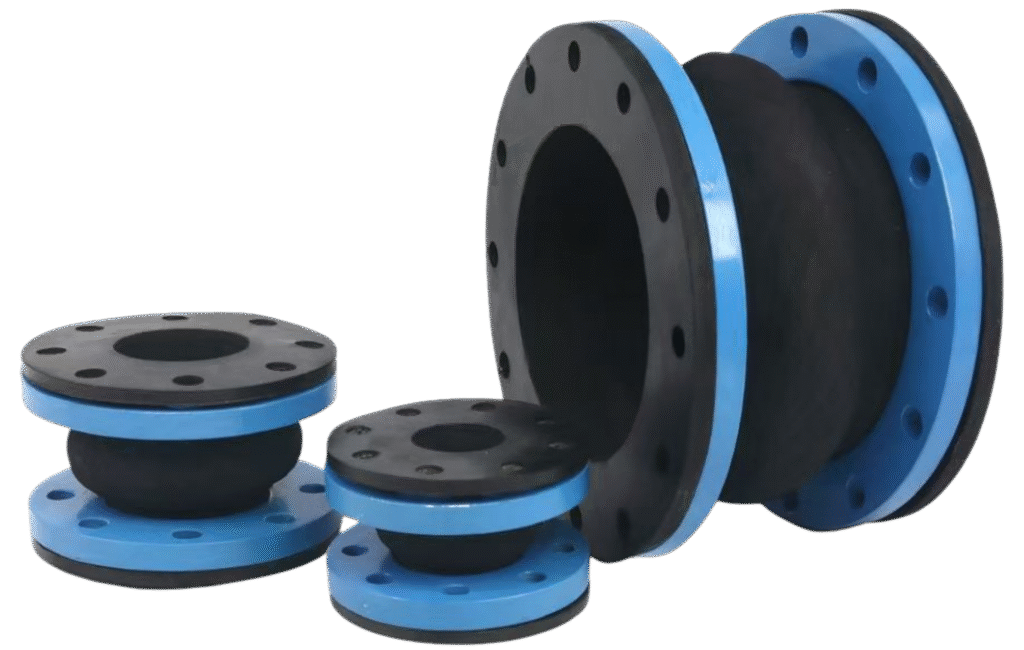

PTFE-Lined Rubber Expansion Joint

The PTFE-lined rubber expansion joint features a layer of PTFE lining inside the rubber bellows, combining excellent corrosion resistance and high-temperature performance. It is ideal for conveying strong acids, alkalis, and high-temperature media. With superior sealing and extended service life, it is the perfect piping solution for chemical, pharmaceutical, food, and other industries.

PTFE Lined Expansion Joints for High-Performance Corrosion Resistance in Industrial Applications

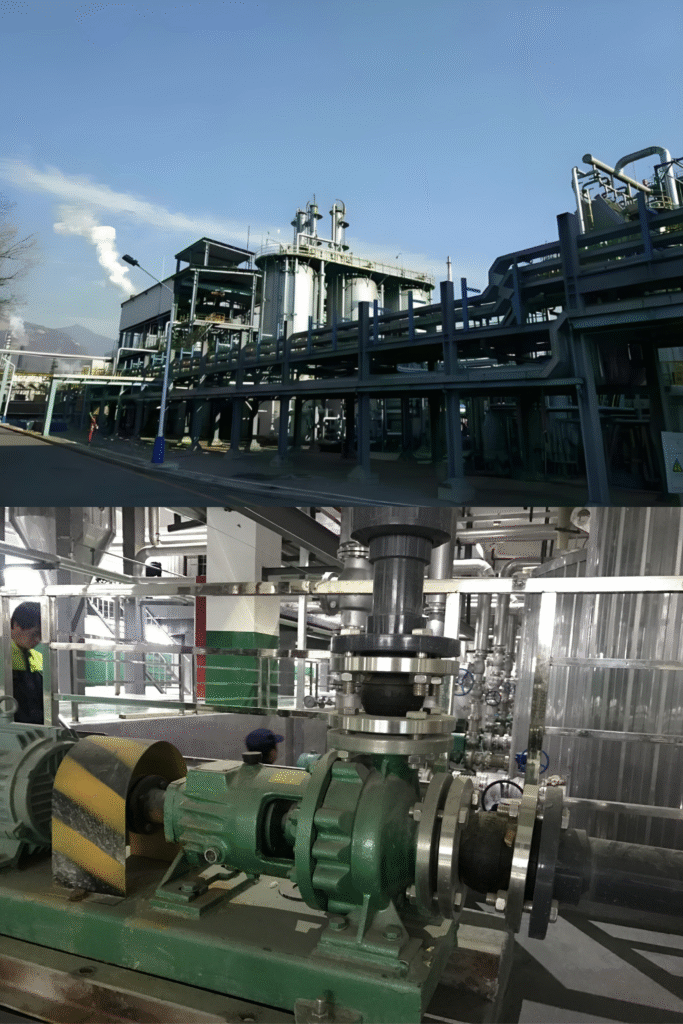

The PTFE lined expansion joints are specifically engineered to withstand harsh and demanding corrosive chemical environments, making them ideal for use in chemical and petrochemical processing facilities, as well as highly corrosive industrial piping systems and pollution control equipment. These expansion joints utilize high-quality PTFE (polytetrafluoroethylene) as the lining material, providing exceptional resistance against aggressive chemicals such as strong acids, alkalis, and various other corrosive media. This ensures long-term reliability and stability of the piping systems in which they are installed.

In particular, PTFE lined expansion joints have gained widespread acceptance in the paper industry. The paper manufacturing process often involves exposure to high temperatures, high pressures, and a range of corrosive substances that conventional metal or plastic expansion joints cannot adequately withstand. Thanks to their outstanding corrosion resistance and durability under elevated temperature and pressure conditions, PTFE lined expansion joints significantly extend equipment lifespan while reducing maintenance costs and minimizing downtime.

Moreover, these expansion joints feature a compact design, ease of installation, and excellent flexibility and movement compensation capabilities. They effectively absorb thermal expansion, vibration, and displacement within piping systems, ensuring the safety and reliability of the entire infrastructure. Due to their unique material advantages and superior performance, PTFE lined expansion joints are widely used across multiple industries and have become an indispensable component in corrosion-resistant piping systems.

The right side shows our Songjiang rubber expansion joint installed in a chemical pipeline application.

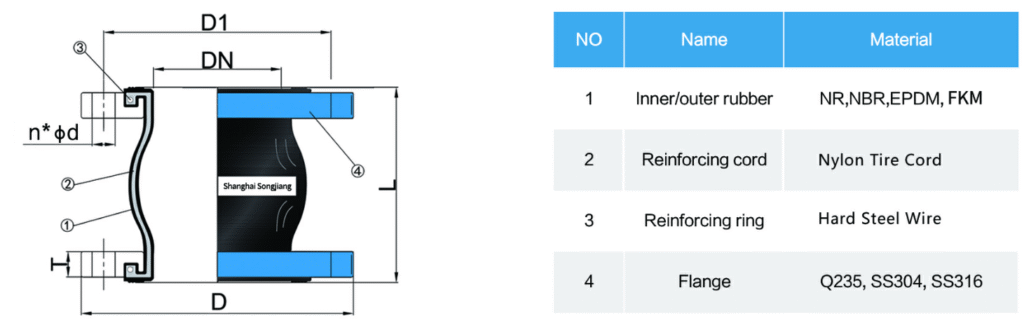

PTFE Lined Rubber Expansion Joint – Standard Dimensions

| Nominal Diameter (DN) | Inch Size (“) | Length (L) mm | Flange Outer Diameter (OD) mm | Bolt Circle Diameter (PCD) mm | Hole Diameter (d) mm | Number of Bolts |

|---|---|---|---|---|---|---|

| DN32 | 1¼” | 95 | 135 | 100 | 18 | 4 |

| DN40 | 1½” | 95 | 145 | 110 | 18 | 4 |

| DN50 | 2″ | 105 | 160 | 125 | 18 | 4 |

| DN65 | 2½” | 115 | 180 | 145 | 18 | 4 |

| DN80 | 3″ | 135 | 195 | 160 | 18 | 8 |

| DN100 | 4″ | 150 | 215 | 180 | 18 | 8 |

| DN125 | 5″ | 165 | 245 | 210 | 18 | 8 |

| DN150 | 6″ | 180 | 280 | 240 | 22 | 8 |

| DN200 | 8″ | 200 | 335 | 295 | 22 | 8 |

| DN250 | 10″ | 225 | 405 | 355 | 26 | 12 |

| DN300 | 12″ | 250 | 460 | 410 | 26 | 12 |

| DN350 | 14″ | 250 | 520 | 470 | 26 | 16 |

| DN400 | 16″ | 250 | 580 | 525 | 30 | 16 |

| DN450 | 18″ | 250 | 640 | 585 | 30 | 20 |

| DN500 | 20″ | 250 | 715 | 650 | 33 | 20 |

| DN600 | 24″ | 260 | 840 | 770 | 36 | 20 |

| DN700 | 28″ | 280 | 910 | 840 | 36 | 24 |

| DN800 | 32″ | 300 | 1020 | 950 | 39 | 24 |

| DN900 | 36″ | 320 | 1120 | 1050 | 39 | 28 |

| DN1000 | 40″ | 340 | 1255 | 1170 | 42 | 28 |

| DN1200 | 48″ | 360 | 1485 | 1390 | 48 | 32 |

Note: The PTFE lining is typically 1–2 mm thick, but the thickness may vary depending on the model. If you have specific requirements for thickness, material, or chemical compatibility, feel free to contact us for customized solutions.