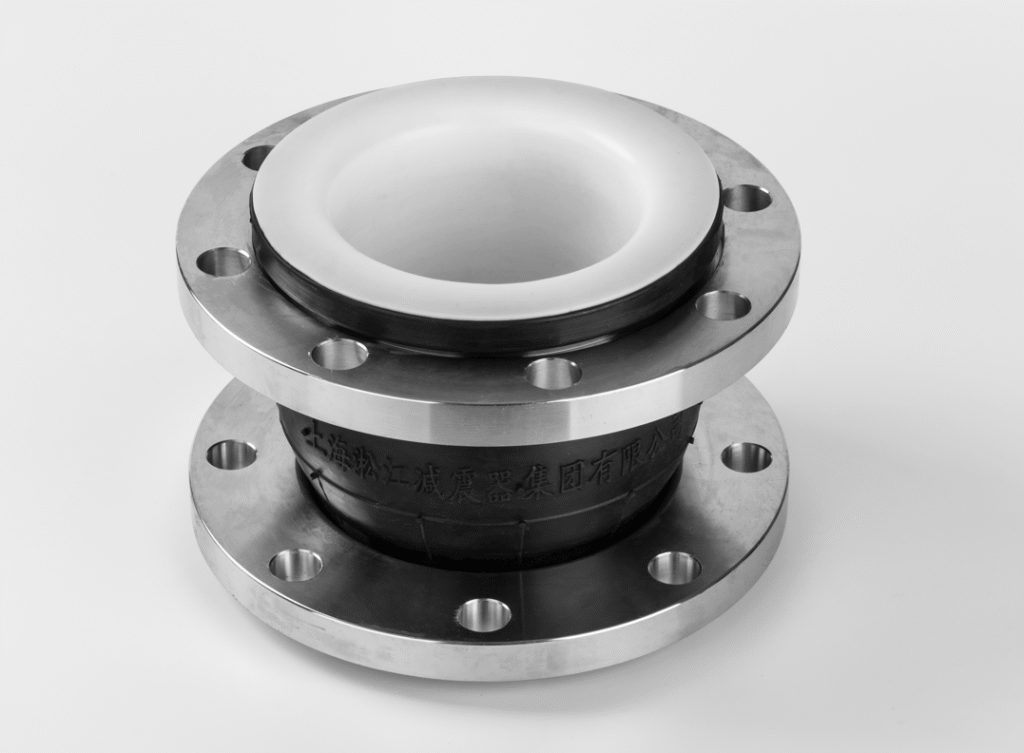

PTFE EXPANSION JOINTS

PRODUCT > PTFE EXPANSION JOINTS

What is a PTFE Expansion Joint?

A PTFE expansion joint is a flexible connector made from PTFE (Polytetrafluoroethylene) material, specifically designed for piping systems that require high corrosion resistance and purity. It is also commonly referred to as a "TFE expansion joint" or "Teflon expansion joint." This type of expansion joint is manufactured using high-purity PTFE through an isostatic molding process, ensuring uniform wall thickness and consistent quality across the product line. PTFE is renowned for its exceptional chemical resistance and extremely long service life, capable of withstanding aggressive media such as strong acids, alkalis, and organic solvents. It is an ideal solution for demanding operating conditions.

PTFE expansion joints can be designed in two structural forms depending on the specific working conditions and application requirements:

PTFE-lined rubber expansion joints, where a PTFE liner is embedded inside the rubber bellows. This structure combines the flexibility and movement compensation capabilities of rubber with the excellent chemical resistance of PTFE. It is ideal for systems that require some flexibility while handling corrosive media.

Fully-formed PTFE bellows, which are made entirely from PTFE through an isostatic molding process. These offer outstanding chemical stability and purity, making them suitable for highly aggressive environments or applications with stringent purity requirements, such as in the chemical, pharmaceutical, or food industries.

The appropriate structure should be selected based on actual working parameters such as the type of medium, temperature, pressure, and installation environment. Choosing the right type ensures optimal performance, safety, and longevity of the product.

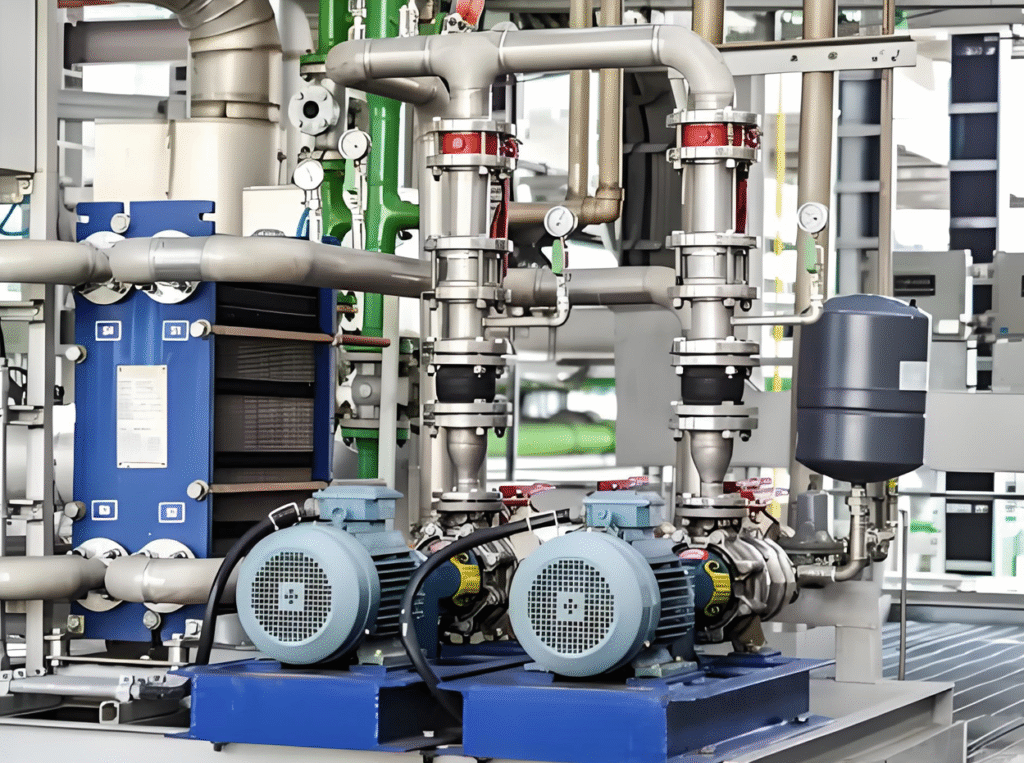

Our project case

This project is a customized application of PTFE-lined rubber expansion joints for the chemical pump system at the BASF plant. These joints are specifically designed for transporting highly corrosive chemical media and are suitable for harsh conditions involving acids, alkalis, and organic solvents.

What are the Types of PTFE Expansion Joints?

PTFE expansion joints come in various types based on the number of convolution rings, structural design, and flange connection options to meet different operating requirements. Common types include: Two-convolution PTFE expansion joints: Compact design suitable for applications with limited installation space, offering basic displacement absorption capabilities. Three-convolution PTFE expansion joints: Provide greater axial movement compensation, ideal for medium-length compensation needs in piping systems. Five-convolution PTFE expansion joints: Designed for systems requiring a wider range of movement compensation and enhanced flexibility, with improved vibration damping. All types are available with standard flange connections or custom flange options, making them ideal alternatives to traditional metal or lap joint connectors. In addition to outstanding chemical resistance, PTFE expansion joints offer excellent sound insulation, easy installation, and long service life. Standard sizes range from 1 inch to 12 inches, with custom sizes available up to 48 inches. Different lengths (face-to-face dimensions), displacement compensation capabilities, pressure, and temperature ratings can be selected to suit various specifications and application environments.

How to Choose the Right PTFE Expansion Joint Structure Based on Pressure?

When selecting a PTFE expansion joint, the pressure range of the system is a key factor. The following recommendations are based on different pressure conditions:

Pressure range: 0.6 – 1.6 MPa

It is recommended to use a stainless steel bellows compensator lined with PTFE, which offers both pressure resistance and corrosion resistance. This structure is suitable for high-pressure and highly corrosive environments.Pressure range: 0.1 – 0.6 MPa

A composite structure with a PTFE lining and stainless steel braided mesh is recommended. This enhances external protection and tensile strength, making it ideal for medium-pressure applications.Pressure range: below 0.1 MPa (low-pressure systems)

A pure PTFE bellows compensator with an external stainless steel limit ring can be used. This setup meets flexibility requirements while preventing overextension or collapse under low pressure.

Is the PTFE Expansion Joint Suitable for Vacuum Systems?

Yes, PTFE expansion joints are highly suitable for vacuum systems. Their reinforced convoluted structure is designed to maintain dimensional stability under negative pressure, preventing collapse or deformation. Additionally, PTFE (polytetrafluoroethylene) is extremely chemically inert, making it resistant to corrosive media commonly found in vacuum environments. It also prevents gas permeation and leakage.

This makes PTFE expansion joints ideal flexible connectors for high-purity and high-vacuum applications, ensuring long-term performance and system integrity.

Our PTFE expansion joints are rated for temperatures from -300°F to 400°F and pressures from full vacuum up to 160 psi, depending on the number and type of convolutions used.

What are the Advantages of PTFE Expansion Joints in Various Industries?

PTFE expansion joints offer significant advantages in industries such as chemical, pharmaceutical, semiconductor, food processing, power generation, petrochemical, flue gas treatment, and vacuum systems, especially in applications requiring high corrosion resistance, high purity, or extreme temperature conditions.

Key advantages include:

Exceptional corrosion resistance: PTFE can withstand almost all strong acids, alkalis, and solvents, making it ideal for chemical, pharmaceutical, and flue gas treatment industries.

Suitable for vacuum and high-purity systems: Its reinforced bellows design maintains stability under vacuum without deformation, and the inert material does not contaminate the medium—perfect for semiconductor, electronics, and biopharmaceutical industries.

Excellent high and low temperature performance: Operating temperature range from -300°F to 400°F, suitable for extremely cold or hot environments such as power generation and thermal energy transport.

Flexible structural design: Available in 2, 3, or 5 convolution bellows to meet various displacement compensation and pressure requirements.

Long service life with low maintenance: PTFE’s outstanding aging and fatigue resistance reduces replacement frequency.

Easy installation with compact face-to-face length: Its compact design fits well in tight spaces, enhancing system integration efficiency.

Because of these corrosion resistance, temperature tolerance, vacuum suitability, and structural flexibility, PTFE expansion joints are widely favored across demanding industries and serve as an ideal alternative to traditional metal joints.

Do PTFE Expansion Joints Age or Become Brittle?

Compared to many traditional elastomeric materials on the market, PTFE demonstrates outstanding aging resistance. Some materials available today tend to become brittle, crack, or degrade in performance after prolonged exposure to high temperatures, high pressure, UV radiation, or chemical corrosion, which can compromise system safety and stability.

However, our company’s PTFE expansion joints are manufactured using high-purity raw materials and advanced isostatic molding technology, ensuring excellent physical stability and durability. Even under harsh conditions, they maintain structural integrity without aging or becoming brittle, guaranteeing long-term reliability.

Not only do our PTFE expansion joints offer superior quality, but we also provide comprehensive service, including professional technical support and customized solutions. This helps customers minimize maintenance costs and reduce system downtime risks. By choosing us, you gain durable products and worry-free after-sales assurance.