Multiple Arch Fully Hand-Wrapped Rubber Expansion Joint

Home > Multiple Arch Fully Hand-Wrapped Rubber Expansion Joint

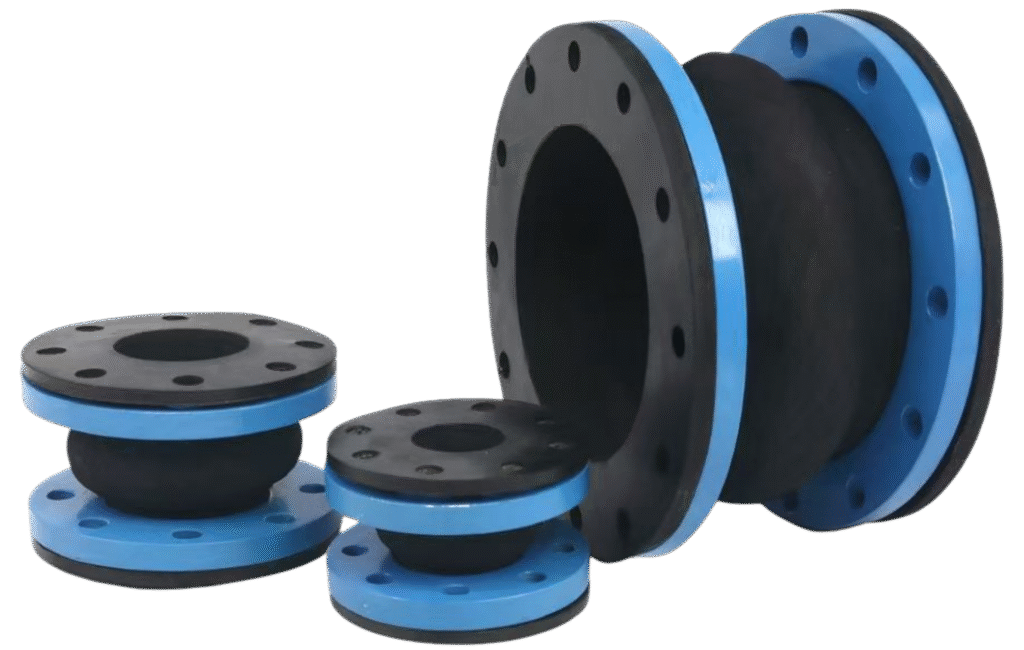

Multiple Arch Full Face Rubber Expansion Joint

Our Full Faced Molded Rubber Expansion Joints are precision-molded from high-quality rubber compounds, designed to absorb vibration, reduce noise, and compensate for thermal expansion and contraction in piping systems. Featuring an integral full-face rubber flange, this joint ensures excellent sealing and corrosion resistance without the need for gaskets. Ideal for HVAC, water treatment, chemical processing, and general industrial applications, it offers superior flexibility, long service life, and easy installation.

Advantages of Single Arch Hand-Wrapped Rubber Expansion Joint

Higher Structural Strength: Manufactured with multiple layers of rubber and fabric reinforcement through hand-wrapping, providing superior strength and durability under pressure and deformation.

Suitable for Large-Diameter Pipes: The winding process allows the production of expansion joints for large diameters and high-pressure conditions, overcoming the size limitations of traditional molded joints.

Excellent Fatigue Resistance: The hand-wrapped construction resists cracking or delamination under repeated deformation, ensuring a longer service life.

Outstanding Compensation Ability: Effectively absorbs axial, lateral, and angular movements, reducing stress concentration in the piping system and improving operational stability.

Flexible Customization: Rubber material, reinforcement structure, and wall thickness can be tailored to meet specific requirements for different media, temperatures, and pressures.

Superior Corrosion and Wear Resistance: Optional materials offer excellent resistance to corrosion, high temperature, oil, and abrasion, making it suitable for a wide range of industrial environments.

Vibration and Noise Reduction: The elastic and damping properties of the rubber material effectively minimize vibration and noise, enhancing the smooth operation of equipment.

WCR Wound Rubber Expansion Joints model selection

Type

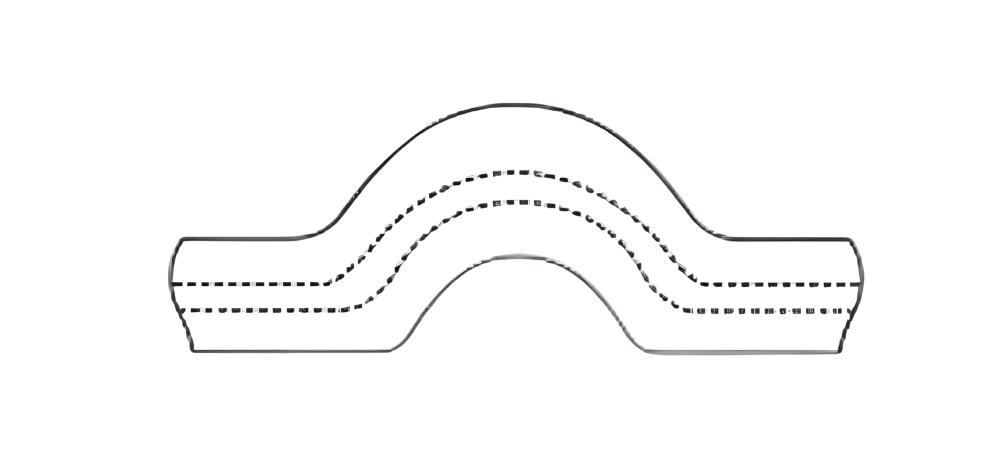

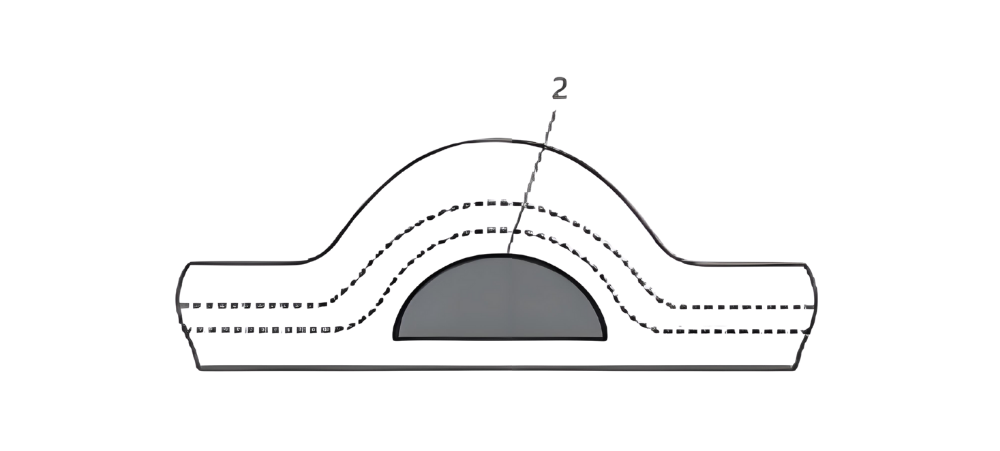

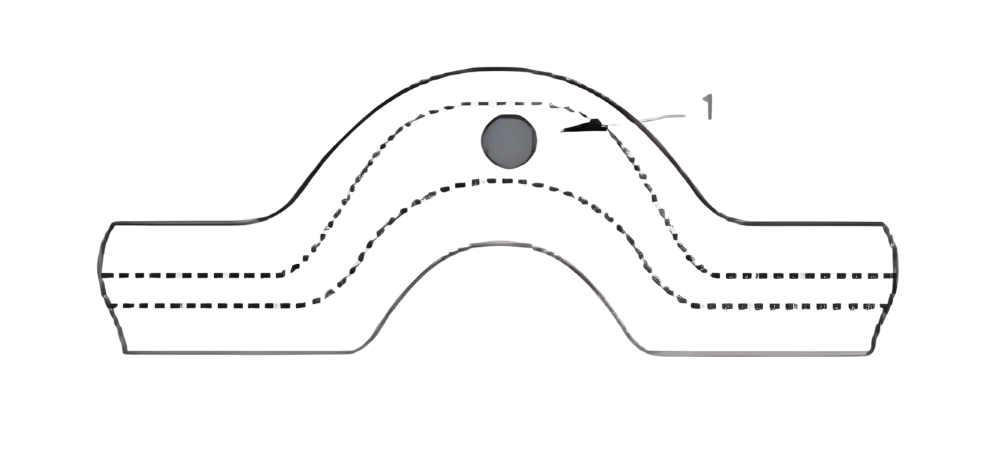

Structural diagram

Describe

Standard

Suitable for above-ground conventional pipelines under normal pressure.

Flat inner bore

Suitable for pipelines containing debris or when the medium flow rate is too high: 2 layers of high-molecular rubber.

Built-in steel ring

Suitable for high-pressure applications: 1 steel ring.

Built-in steel ring with flat inner bore

Suitable for high-pressure pipelines containing debris or when the medium flow rate is too high: 1 steel ring + 2 layers of high-molecular rubber.

Inner steel ring with flat inner bore

Suitable for underground, negative pressure, or pipelines containing debris or when the medium flow rate is too high: 1 steel ring.

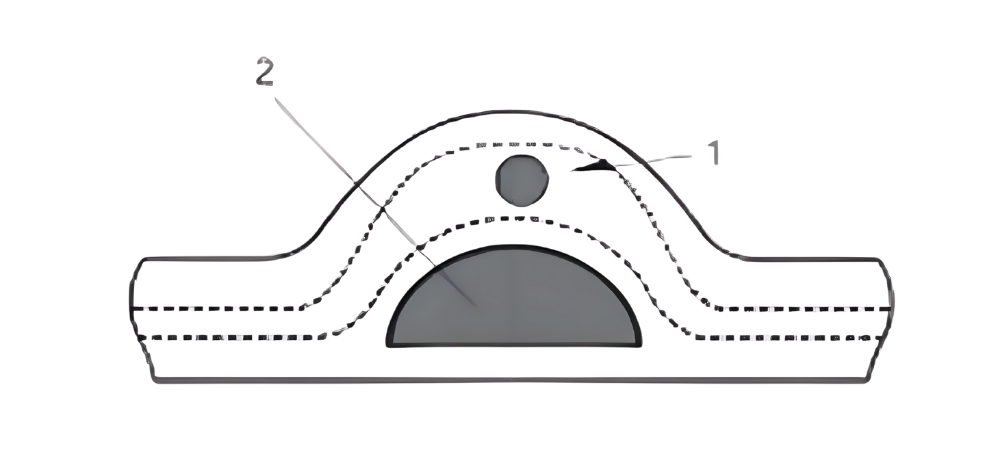

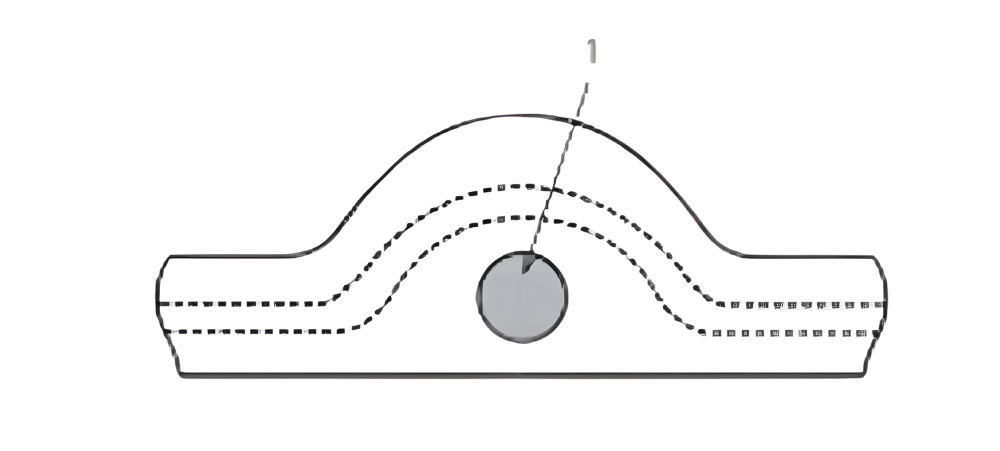

WCR Wound Rubber Expansion Joints Type of sealing surface

Type

Structural diagram

Describe

Convex seal

Convex seal with built-in O-ring to prevent pull-off; flange can be rotated for easy installation.

Loose flange

Full-face seal with a larger sealing area to prevent leakage; loose-sleeve split flange requires attention to aligning bolt holes on both pipe ends during installation.

Fixed flange

Flange vulcanized integrally with the sealing face for high pressure resistance and to prevent pull-off.

Built-in O-ring

Sealing face with built-in steel ring, where the steel ring’s outer diameter does not exceed the bolt hole’s inner diameter.

Built-in flange

Sealing face with built-in flange, flange dimensions match the sealing face, suitable for high-pressure applications.

Built-in T-pipe

Flange with connecting pipe, flange vulcanized integrally with the sealing face, with built-in T-pipe, suitable for ultra-high-pressure applications.

Multiple Arch Fully Hand-Wrapped Rubber Expansion Joint – Size Chart (士300mm)

| Pipeline diameter | length | Number of ripples | Movement absorption for the standard | Standard pressure | Max pressure | ||||

|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | in | (mm) | pcs | ax+ (mm) | ax- (mm) | lat± (mm) | Δ±° | (bar) | (bar) |

| 20 | 3/4″ | 550 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 25 | 1″ | 550 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 32 | 11/4″ | 550 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 40 | 11/2″ | 550 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 50 | 2″ | 550 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 65 | 2 1/2″ | 650 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 80 | 3″ | 650 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 100 | 4″ | 650 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 125 | 5″ | 650 | 5 | 60 | 50 | 300 | 30 | 16 | 25 |

| 150 | 6″ | 650 | 5 | 60 | 60 | 300 | 30 | 16 | 25 |

| 200 | 8″ | 700 | 5 | 80 | 60 | 300 | 30 | 16 | 25 |

| 250 | 10″ | 700 | 5 | 80 | 60 | 300 | 20 | 10 | 16 |

| 300 | 12″ | 800 | 5 | 80 | 60 | 300 | 20 | 10 | 16 |

| 350 | 14″ | 900 | 5 | 80 | 60 | 300 | 15 | 10 | 16 |

| 400 | 16″ | 900 | 5 | 80 | 70 | 300 | 15 | 10 | 16 |

| 450 | 18″ | 900 | 5 | 80 | 70 | 300 | 15 | 10 | 16 |

| 500 | 20″ | 900 | 5 | 80 | 70 | 300 | 10 | 10 | 16 |

| 600 | 24″ | 1000 | 6 | 80 | 70 | 300 | 10 | 10 | 16 |

Ordering Information

When placing an order for Full Faced Molded Rubber Expansion Joints, please kindly confirm the following details to ensure correct product selection:

Nominal diameter (in mm or inch)

Working pressure and temperature of the system

Medium type (e.g., water, air, oil, chemicals)

Rubber material requirement (e.g., EPDM for hot water, NBR for oil, Neoprene for general use)

Flange material (e.g., carbon steel, stainless steel, galvanized)

Flange drilling standard (e.g., DIN, ANSI, JIS, BS, or customized according to your drawing)

Quantity needed and expected delivery time

Since the product is mold-formed, the dimensions are fixed. However, we can fully customize the rubber compound and flange specifications according to your application requirements.

For special working conditions or installation limitations, feel free to contact our technical team for assistance at [email protected] or via WhatsApp at +86 13032112360. We’re here to help you find the ideal solution for your project.

Multiple Arch Fully Hand-Wrapped Rubber Expansion Joint – Size Chart (士400mm)

| Pipeline diameter | length | Number of ripples | Movement absorption for the standard | Standard pressure | Max pressure | ||||

|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | in | (mm) | pcs | ax+ (mm) | ax- (mm) | lat± (mm) | Δ±° | (bar) | (bar) |

| 20 | 3/4″ | 750 | 7 | 80 | 50 | 400 | 30 | 16 | 25 |

| 25 | 1″ | 750 | 7 | 80 | 50 | 400 | 30 | 16 | 25 |

| 32 | 11/4″ | 750 | 7 | 80 | 50 | 400 | 30 | 16 | 25 |

| 40 | 11/2″ | 750 | 7 | 80 | 50 | 400 | 30 | 16 | 25 |

| 50 | 2″ | 750 | 7 | 80 | 50 | 400 | 30 | 16 | 25 |

| 65 | 2 1/2″ | 750 | 6 | 80 | 50 | 400 | 30 | 16 | 25 |

| 80 | 3″ | 750 | 6 | 80 | 50 | 400 | 30 | 16 | 25 |

| 100 | 4″ | 750 | 6 | 80 | 50 | 400 | 30 | 16 | 25 |

| 125 | 5″ | 750 | 6 | 80 | 50 | 400 | 30 | 16 | 25 |

| 150 | 6″ | 750 | 6 | 100 | 60 | 400 | 30 | 16 | 25 |

| 200 | 8″ | 850 | 7 | 100 | 60 | 400 | 30 | 16 | 25 |

| 250 | 10″ | 950 | 7 | 100 | 60 | 400 | 20 | 10 | 16 |

| 300 | 12″ | 1100 | 7 | 100 | 60 | 400 | 20 | 10 | 16 |

| 350 | 14″ | 1100 | 7 | 100 | 60 | 400 | 20 | 10 | 16 |

| 400 | 16″ | 1100 | 7 | 100 | 70 | 400 | 15 | 10 | 16 |

| 450 | 18″ | 1100 | 7 | 100 | 70 | 400 | 15 | 10 | 16 |

| 500 | 20″ | 1100 | 7 | 100 | 70 | 400 | 15 | 10 | 16 |

| 600 | 24″ | 1250 | 7 | 100 | 70 | 400 | 10 | 10 | 16 |

Ordering Information

When placing an order for Full Faced Molded Rubber Expansion Joints, please kindly confirm the following details to ensure correct product selection:

Nominal diameter (in mm or inch)

Working pressure and temperature of the system

Medium type (e.g., water, air, oil, chemicals)

Rubber material requirement (e.g., EPDM for hot water, NBR for oil, Neoprene for general use)

Flange material (e.g., carbon steel, stainless steel, galvanized)

Flange drilling standard (e.g., DIN, ANSI, JIS, BS, or customized according to your drawing)

Quantity needed and expected delivery time

Since the product is mold-formed, the dimensions are fixed. However, we can fully customize the rubber compound and flange specifications according to your application requirements.

For special working conditions or installation limitations, feel free to contact our technical team for assistance at [email protected] or via WhatsApp at +86 13032112360. We’re here to help you find the ideal solution for your project.