Exhaust Duct Expansion Joint

Home > Exhaust Duct Expansion Joint

Exhaust Duct Expansion Joint

Our fabric (non-metallic) expansion joints are specially designed for gas turbine diffuser systems operating under high temperature and pressure pulse conditions. They feature a multi-layer textile structure that ensures excellent flexibility, high temperature resistance, and reliable sealing performance. By compensating for thermal expansion, vibration, and installation tolerances, these joints effectively reduce stress concentration, protect connected equipment, and guarantee long-term operational safety.

Smoke Extraction Fan Expansion Joint – High-Temperature, Self-Sealing Fabric Design

Overview:

Our smoke extraction fan expansion joints are specially designed for high-temperature applications, providing reliable vibration compensation and sound isolation in smoke extraction systems for buildings and tunnels. These joints are suitable for both round and rectangular duct cross-sections and can be tailored to your specific installation requirements.

Key Features:

Design: Straight or conical fabric expansion joints, silicon-free, with self-sealing full-faced flanges.

Flanges: Single-part backing flange on both sides ensures secure and leak-proof installation.

Test Temperature: Tested for continuous operation at 600°C for 120 minutes.

Test Vacuum: 1,500 Pa at room temperature; 500 Pa at 600°C.

Installation Method: Fixed to flanges at duct level for easy integration.

Dimensions: Suitable for round and rectangular ducts; installation length from 100 mm to 250 mm.

Media Temperature: Long-term operation up to 120°C.

Pressure Resistance: Up to ±15,000 Pa at room temperature.

Movement Capability: Accommodates both axial and lateral movements, with axial compression up to 50 mm and lateral displacement up to 20 mm.

Applications:

Ideal for automatic smoke extraction systems in buildings and tunnels, providing vibration compensation, noise reduction, and safe smoke evacuation under high-temperature conditions.

Expansion Joint Flanges and Flow Liners – Materials, Design, and Accessories

Flanges Design:

Type: Single-part backing flange with clearance holes for easy installation.

Standards: Designed according to the usual norms for ventilation systems.

Materials: Carbon steel or stainless steel.

Coating Options: Primed, hot-dip galvanised, or special paint for enhanced corrosion resistance.

Flow Liners Design:

Type: Cylindrical, conical, or telescoping (detailed designs > page 360).

Materials: Carbon steel or stainless steel.

Coating Options: Primed, hot-dip galvanised, or special paint.

Optional Accessories:

Support Rings: For enhanced stability and alignment.

Cross Section: BGS600 S21.

Vacuum Ring: Made from spring steel to ensure durability under negative pressure.

Overview:

These expansion joint components are designed for ventilation and smoke extraction systems, offering reliable performance, ease of installation, and long-term durability. Flanges and flow liners can be customised according to project requirements, with a variety of materials and coatings to suit different operating environments.

Expansion joints for smoke extraction and ventilation

| Name | Description | Pressure | Temperature / Smoke Test | Movement Capability |

|---|---|---|---|---|

| Smoke extraction fan expansion joint with self-sealing full-faced flanges | Round or rectangular duct cross-section | Up to ±15,000 Pa | 120 min smoke extraction at 600°C | Axial and lateral |

| Smoke extraction single-arch ducting expansion joint with vacuum ring and self-sealing full-faced flanges | Round or rectangular duct cross-section | Up to ±15,000 Pa | 120 min smoke extraction at 600°C | Axial and lateral |

| Fan or ducting expansion joint with self-sealing full-faced flanges for ventilation and air conditioning systems | Round or rectangular duct cross-section | Up to ±15,000 Pa | -60 to +200°C (peaks up to 250°C) | Axial and lateral |

| Conductive fan or ducting expansion joint with explosion protection and self-sealing full-faced flanges | Round or rectangular duct cross-section | Up to ±15,000 Pa | -30 to +100°C | Axial and lateral |

What is an exhaust duct expansion joint and where is it used?

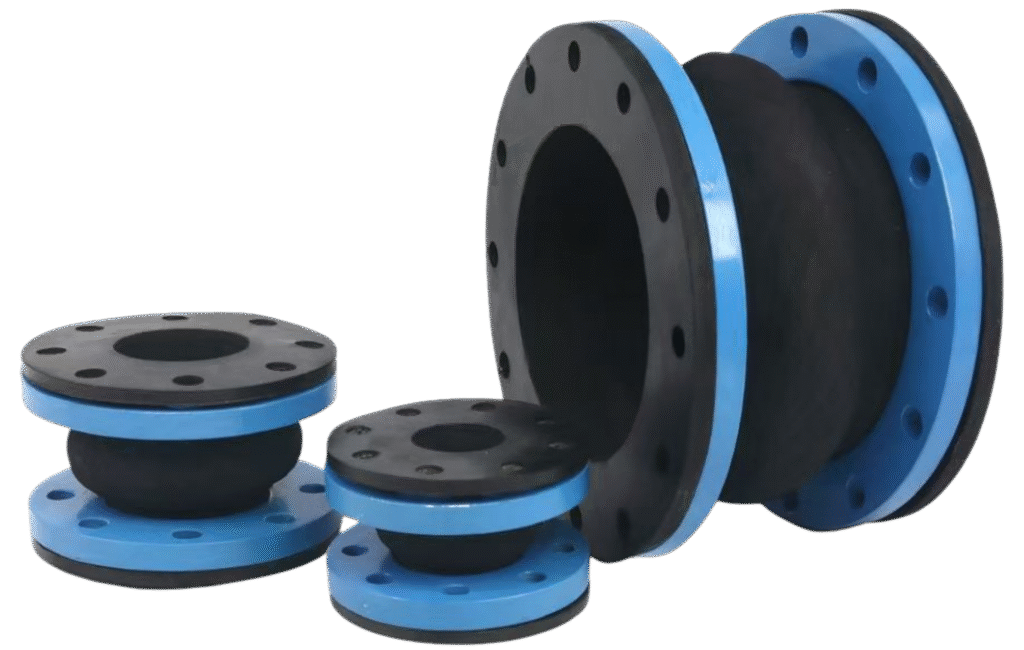

An exhaust duct expansion joint is a flexible connector designed to absorb thermal expansion, vibration, and installation misalignment in duct systems. It is usually made of multi-layer non-metallic fabric materials, offering high-temperature resistance and excellent sealing performance. It is widely used in power plant flue gas ducts, gas turbine diffuser ducts, industrial furnaces and boilers, tunnel and building smoke extraction systems, and large-scale HVAC exhaust lines. By compensating for thermal movement and vibration, it protects connected equipment, extends system service life, and reduces noise and vibration impact on the environment.

Why choose fabric expansion joints over metal or rubber types?

Fabric expansion joints are lightweight, flexible, and highly adaptable, providing large axial, lateral, and angular movement compensation without generating reaction thrust. Compared to metal joints, they have lower stiffness and reduce stress concentration in ducts; compared to rubber joints, they withstand higher temperatures (up to 1000°C) and resist chemical corrosion. Multi-layer construction allows customization for high temperature, corrosive gases, or enhanced pressure resistance, making them suitable for complex industrial conditions.

What are the main advantages of exhaust duct fabric expansion joints?

Thermal expansion and vibration compensation: Effectively absorbs pipe expansion, mechanical vibration, and foundation settlement

Noise and vibration reduction: Textile layers and insulation provide sound and vibration dampening

High temperature and corrosion resistance: Multi-layer design withstands hot flue gas and chemical exposure

Easy installation and maintenance: Lightweight and flexible, enabling quick installation and replacement

No reaction thrust: Eliminates axial load transfer, simplifying system design

What are the key applications of exhaust duct expansion joints?

Power plant flue gas ducts and smoke exhaust systems

Gas turbine diffuser systems

Industrial furnace and boiler exhaust

Tunnel and building smoke extraction systems

Large HVAC exhaust lines

Any high-temperature or chemically aggressive gas duct system requiring flexibility and vibration isolation

What should be considered during installation and maintenance?

Ensure proper flange alignment, avoid sharp edges or welding slag that could damage the fabric, and tighten bolts to specified torque. In extreme high-temperature environments, insulation can be applied to extend service life. Regular inspections of wear and sealing conditions, along with timely replacement of aging components, ensure safe and stable long-term operation.

All expansion joint products can be customized according to actual project requirements, including dimensions, materials, temperature range, and accessory configuration, to meet the specific installation and operational needs of different duct systems.