FABRIC EXPANSION JOINTS

PRODUCT > FABRIC EXPANSION JOINTS

What is a Fabric Expansion Joint?

A fabric expansion joint is a flexible, non-metallic component designed specifically for use in systems that transport gases, not liquids, due to its unique composition of layers. These joints are capable of withstanding extremely high temperatures, reaching up to 1000°C. Unlike rubber or metallic counterparts, fabric expansion joints are highly flexible, with negligible spring rate. They consist of multiple layers, each with a distinct purpose. Some materials are designed to reduce heat, others protect against corrosive effects from the fluid being processed, and some are made to handle internal pressure. By combining these layers, a structure with the necessary properties for specific conditions is created. For this reason, fabric expansion joints are incredibly versatile and can be adapted to a wide range of applications.

Our project case

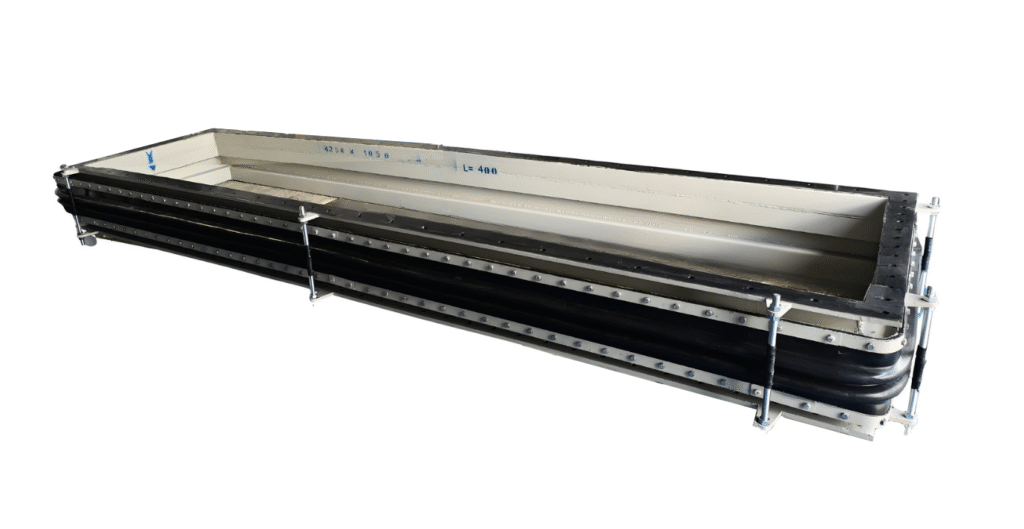

A 7.6-meter-long fabric expansion joint installed at the exhaust duct outlet of the heat recovery boiler in a gas turbine power plant.

Fabric Expansion Joint Classifications

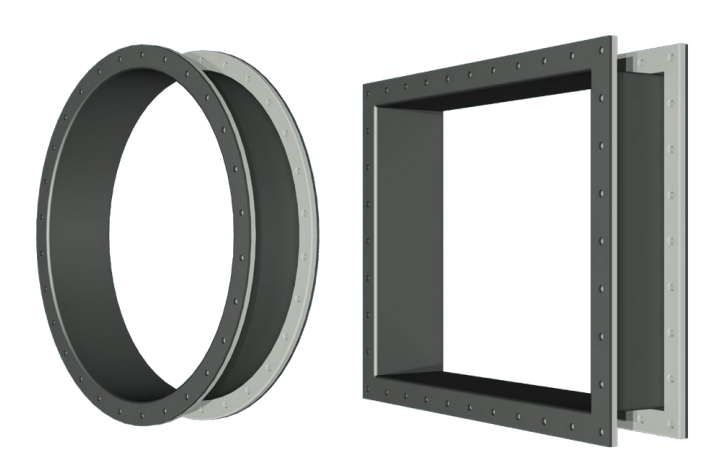

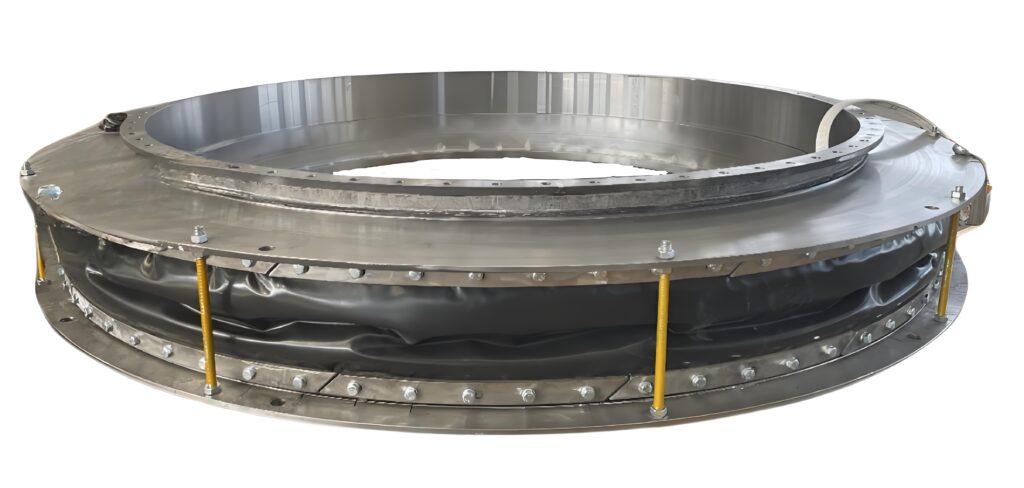

Fabric expansion joints can be classified based on temperature resistance (low, medium, and high temperature), structure (single-layer or multi-layer), shape (round, rectangular, or conical), and connection method (flanged or sleeve type). Each type is designed to meet specific working conditions in ventilation, flue gas, and exhaust systems.

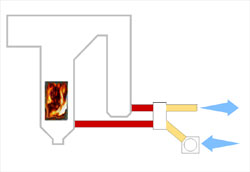

What is the function of this expansion joint?

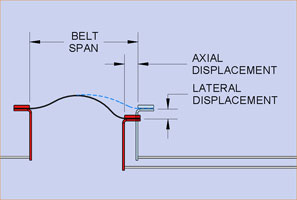

When properly installed in a piping system, this type of expansion joint effectively absorbs dimensional changes caused by temperature fluctuations. By accommodating thermal expansion, it helps maintain the stability of the piping system, preventing damage or leakage due to thermal stress, thus enhancing the long-term reliability and safety of the system.

A fabric expansion joint is installed in duct systems at points where movement or thermal expansion is expected. It consists primarily of two elements: a flexible fabric element that serves as a gas seal, and mounting metal frames. The fabric seal forms a continuous loop, similar to a band, and its edges are secured within the metal frames, which are connected to the ends of the duct sections. As the ducts shift or vibrate, the fabric element flexes accordingly. This material must withstand the movement without cracking or leaking, even when subjected to elevated temperatures or aggressive substances.

In more demanding conditions, supporting features such as thermal insulation pads, dust collection shields, or internal sleeves (flow liners) may be added to safeguard the integrity of the fabric. The next section will explore the fundamental components of fabric expansion joints and the principles behind their engineering.

What is integrated design for expansion joints and ducting/piping systems?

Integrated design means incorporating the expansion joint directly into the duct or piping structure during the manufacturing process. This eliminates the need for traditional flanged connections, improving performance and installation efficiency.

What are the advantages of integrated expansion joint design?

Key benefits include:

Elimination of leak risks: No flange gaskets are required, reducing the possibility of leakage.

Reduced onsite installation risks: Sensitive assemblies are pre-installed at the factory, minimizing damage during onsite handling.

Significant labor cost savings: Both manufacturing and installation labor are greatly reduced.

Improved shipping and installation efficiency: The largest possible duct or pipe sections can be shipped to the job site, reducing the number of field connections.

Fewer flanged connections: The need for flanged expansion joint connections is minimized.

Structural integration: The ducting can serve as the expansion joint’s flow liner, and the expansion joint frame can replace traditional duct stiffeners.

Simplified onsite work: No need to assemble flanged expansion joints at the job site, saving time and effort.

What kind of projects benefit most from this design?

This integrated approach is ideal for projects requiring high sealing performance, efficient installation, and minimal onsite labor, such as power plants, chemical facilities, tunnel ventilation systems, and large industrial ducting installations.