Technical Materials Overview — Rubber Expansion Joints

Achieving high performance and reliability in industrial applications often requires incorporating advanced materials and engineering solutions into product design. We provide a wide range of high-performance elastomers and reinforcement materials, carefully selected to meet the demanding requirements of industrial pipelines and mechanical systems. Whether it’s resistance to high temperatures, chemicals, abrasion, or outdoor conditions, our material solutions ensure durable and long-lasting operation.

EPDM (Ethylene Propylene Diene Monomer)

EPDM offers excellent resistance to water, steam, and weather conditions. It is highly resistant to heat, ozone, alkalis, and oxygenated solvents, making it ideal for outdoor applications. Not suitable for petroleum-based oils. Recommended operating temperature ranges from -30°F to 350°F (-34°C to 177°C), making it a versatile industrial elastomer.

Neoprene (Chloroprene Rubber)

Neoprene resists alkalis, inorganic acids, and saline solutions. It is flame retardant, abrasion-resistant, and weatherproof. Shows good resistance to animal and vegetable oils, moderate resistance to petroleum oils. Recommended operating temperature: -20°F to 225°F (-29°C to 107°C).

NR (Natural Rubber)

NR provides excellent elasticity, high tensile strength, and superior resistance to tear and abrasion. It is ideal for applications requiring flexibility and durability. Not suitable for petroleum-based oils or strong solvents. Recommended operating temperature ranges from -40°F to 180°F (-40°C to 82°C), making it a versatile elastomer for industrial rubber expansion joints.

Nitrile Rubber (NBR)

Good resistance to mineral and vegetable oils, greases, hydrocarbon solvents, and dilute acids and alkalis. Recommended temperature range: -10°F to 210°F (-23°C to 99°C).

Hypalon® Equivalent Materials

Provides superior weather, flame, and abrasion resistance, along with excellent resistance to acids, alkalis, and oxidation. Recommended temperature range: -10°F to 250°F (-23°C to 121°C). We offer alternative elastomers with equivalent performance for specific applications.

Hydrogenated Nitrile Rubber (HNBR)

HNBR features a wide operating temperature range (-40°F to 302°F / -40°C to 150°C) and excellent resistance to diverse chemical fluids. It also offers superior wear and ozone resistance, approximately five times higher than standard NBR, bridging the gap for high-temperature oil applications where NBR would fail.

Pure Natural Rubber (Gum Rubber)

High resilience, strong elasticity, excellent tear and abrasion resistance. Recommended temperature range: -40°F to 180°F (-40°C to 82°C).

PTFE Fluoroplastic

Extremely resistant to nearly all industrial chemicals and solvents. Recommended temperature range: -60°F to 450°F (-51°C to 232°C). Teflon® is used where specified.

Viton® / FKM

Outstanding resistance to aggressive chemicals, solvents, and halogenated hydrocarbons. Different grades handle steam, acids, alkalis, and low-temperature flexibility requirements. Operating temperature: -10°F to 400°F (-23°C to 204°C).

Food-Grade and Drinking Water Certified Materials

Certain white and black elastomers meet FDA standards and can be used in direct contact with food, beverages, and pharmaceutical products. EPDM elastomers are also certified for potable water use by the Kunshan Water Plant, making them suitable for drinking water systems.

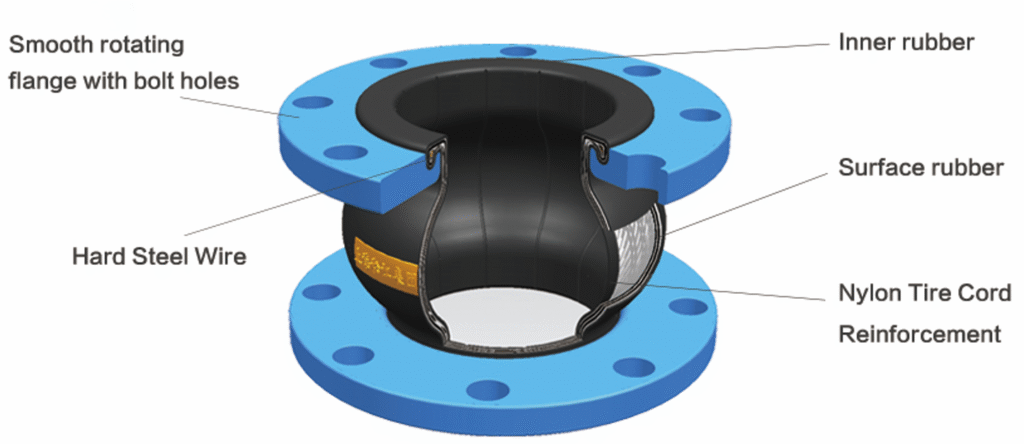

Reinforcement Materials

Polyester, Nylon, and Kevlar® / Aramid Tire Cord

Optimized fiber orientation reduces wall thickness while increasing expansion capability and lowering spring rate. RFL coating ensures excellent adhesion and prevents delamination. Polyester and Nylon perform well up to 300°F (149°C), while Kevlar® / Aramid is suitable for up to 400°F (204°C).

Fiberglass Reinforcement / Insulation Layer

Provides cost-effective reinforcement while acting as insulation for applications up to 1200°F (649°C).

Fiberglass Reinforcement / Insulation Layer

Provides cost-effective reinforcement while acting as insulation for applications up to 1200°F (649°C).

Retaining Rings and Control Unit Materials

Include carbon steel with protective coatings, stainless steel (304/316), and aluminum bronze, selected according to application requirements.

Contact Us for Custom Solutions

Our team is ready to help you select the ideal elastomer and reinforcement combination for your specific application. Whether you require enhanced chemical resistance, high-temperature performance, abrasion protection, or food-grade compliance, we offer custom rubber expansion joint solutions tailored to your industrial piping and equipment needs. Contact us today to discuss your project requirements and get expert recommendations.

For technical inquiries, please contact us at [email protected]