Introduction by Shanghai Songjiang Shock Absorber Group Co., Ltd.

Shanghai Songjiang specializes in producing high-performance EPDM rubber joints, widely used in thermal pipelines, flue gas desulfurization systems, spray coating lines, and more. Below is a comprehensive overview of the properties and applications of EPDM rubber.

1. What is EPDM?

-

Chinese Name: 三元乙丙橡胶

-

English Name: Ethylene Propylene Diene Monomer

-

Abbreviation: EPDM

-

Monomer Composition: Ethylene, Propylene, and a small amount of non-conjugated Diene

-

Key Features: Excellent resistance to oxidation, ozone, weathering, and chemicals

EPDM is a type of synthetic rubber composed of ethylene, propylene, and diene. Its backbone consists of chemically stable saturated hydrocarbons, while the side chains contain unsaturated double bonds. This structure grants EPDM superior resistance to aging, ozone, heat, and weather. EPDM is commonly used in automotive parts, waterproofing membranes, cable insulation, heat-resistant hoses, conveyor belts, and sealing components.

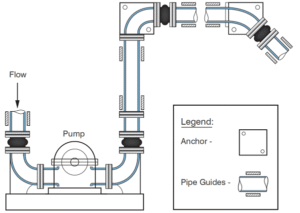

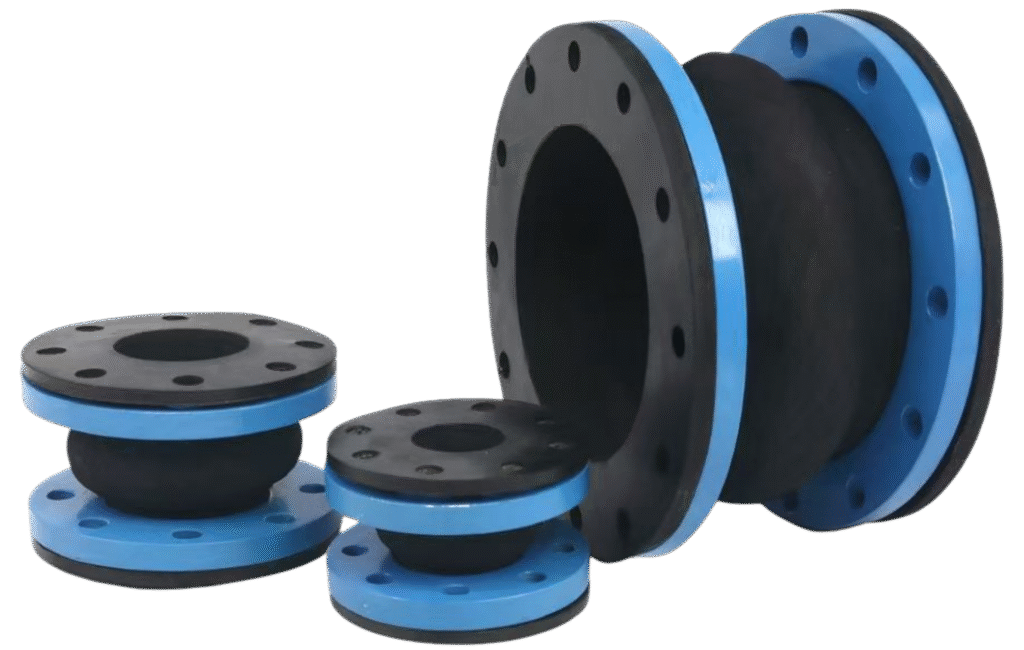

2. Songjiang Group’s EPDM Rubber Expansion Joints

-

Structure: Both inner and outer rubber layers of our joints are made entirely of EPDM.

-

Content: The EPDM content in our joints is around 50%, verified by third-party testing.

-

Raw Materials: We exclusively use Japanese Mitsui EPDM grade 4045 for premium quality.

-

Temperature Resistance: Reliable performance up to 120°C, ideal for boiler rooms, solar energy systems, and thermal pipelines. (Due to 50% EPDM content, the joint is not suitable for extreme temperatures beyond 120°C.)

-

Chemical Resistance: Suitable for weak acids and alkalis, such as lime slurry in FGD systems, seawater desalination, and spray piping applications.

3. Performance Characteristics of EPDM Rubber

1. Low Density and High Fillability

EPDM has a low density (approx. 0.87), enabling high oil extension and filler loading, which helps reduce overall product costs while maintaining physical properties, especially in high Mooney grades.

2. Excellent Aging Resistance

EPDM demonstrates outstanding resistance to ozone, heat, UV, steam, acids, and bases. It remains stable at 120°C for long-term use and can handle short bursts up to 150°C. With peroxide curing systems and proper antioxidants, performance can be further enhanced. In tests, EPDM showed no cracks after 150 hours under 50 pphm ozone and 30% strain.

3. Good Chemical Resistance

Thanks to its saturated molecular backbone, EPDM exhibits low reactivity and excellent resistance to many chemicals including alcohols, acids, bases, oxidizers, refrigerants, detergents, and vegetable oils. However, it is less stable in aromatic or aliphatic hydrocarbons (e.g., gasoline, benzene) and in strong acids over prolonged exposure.

According to ISO/TO 7620, chemical effect levels are classified as follows:

| Grade | Volume Swell (%) | Hardness Loss | Effect on Properties |

|---|---|---|---|

| 1 | <10 | <10 | Minor or none |

| 2 | 10–20 | <20 | Slight |

| 3 | 30–60 | <30 | Moderate |

| 4 | >60 | >30 | Severe |

4. Steam Resistance

EPDM performs better in high-pressure steam environments than many other elastomers. At 230°C steam for nearly 100 hours, it retains its appearance and structure, unlike fluororubber, silicone rubber, or nitrile rubber which degrade more rapidly.

5. Superheated Water Resistance

The performance depends on the curing system. EPDM cured with dithiodimorpholine or TMTD retains mechanical properties after 15 months in 125°C water, with only 0.3% volume expansion. It remains elastic in a wide temperature range from -40°C to -60°C, and suitable for continuous use at 130°C.

6. Electrical Insulation Properties

EPDM has excellent dielectric strength and resistance to corona discharge. It offers superior or comparable performance to SBR, CPE, PE, and XLPE, with a volume resistivity of 10^16 Ω·cm, breakdown voltage of 30–40 MV/m, and a dielectric constant of 2.27 at 1kHz, 20°C.

7. Elasticity

With no polar groups and low cohesive energy, EPDM molecules remain flexible across a wide temperature range. Its elasticity is second only to natural rubber and polybutadiene, and it remains pliable even at low temperatures.

Conclusion

EPDM is a versatile and high-performance rubber material, ideal for applications requiring heat, ozone, and chemical resistance. With carefully selected raw materials and optimized formulation, Songjiang Group ensures reliable and cost-effective rubber joints for demanding industrial systems.