What Is the FZPT-500 Floating Floor Rubber Isolation Pad?

The FZPT-500 pad is a premium elastomer isolation solution designed for floating floors, preventing vibration transmission and structural noise.

It delivers consistent load support while effectively damping vibrations, suitable for industrial, commercial, and acoustic-sensitive installations.

Its engineered rubber formulation ensures reliable performance and long-term durability. The pad minimizes low-frequency vibrations and protects sensitive machinery and flooring, improving operational stability and comfort in floating platform projects.

Why Is FZPT-500 Ideal for Floating Platform and Floor Systems?

Floating floors need materials that combine load-bearing capability with superior vibration isolation, and FZPT-500 meets both requirements.

The pad’s stiffness and damping properties allow floating structures to decouple vibrations without compromising structural integrity or support.

By preventing rigid connections from transmitting vibration, the FZPT-500 enhances acoustic performance and protects building structures. Uniform thickness and predictable deformation make it ideal for large-scale floating floor installations.

Key Performance Factors Considered by Indian Buyers

The Indian customer prioritized load capacity, vibration attenuation, and long-term durability in selecting the FZPT-500.

Stable damping, minimal creep, and consistent isolation performance were decisive factors for project success.

Industrial buyers value reliability under continuous operational stress. The FZPT-500 provides fatigue-resistant, long-lasting performance, ensuring floating platforms remain vibration-free even under heavy machinery or prolonged use.

Installation Advantages and Project Reliability

FZPT-500’s standardized design simplifies installation and ensures consistent performance across large areas.

Modular pads allow quick layout, reduce errors, and provide uniform vibration isolation.

Contractors can achieve faster project timelines and reliable installation quality. Consistent pad dimensions and specifications make construction predictable and minimize the need for adjustments, improving overall efficiency and project reliability.

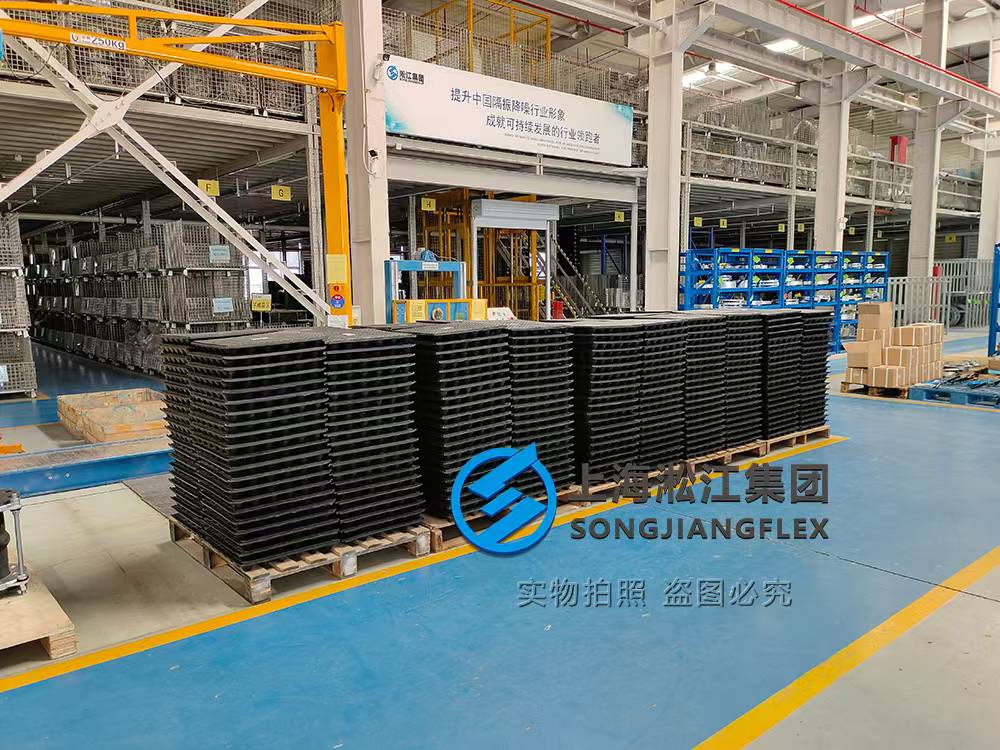

Songjiangflex Quality Assurance for Export Projects

Automated production and rigorous testing ensure the FZPT-500 meets international standards for export projects.

Quality controls verify material properties, durability, and dimensional accuracy, guaranteeing reliable performance.

From automated mixing and molding to testing for fatigue, compression, and temperature resistance, Songjiangflex maintains strict manufacturing standards. Each pad is verified before shipment, providing confidence for overseas floating platform projects.

Materials and Durability Features

High-grade elastomers resist aging, fatigue, and environmental stress, ensuring consistent long-term performance.

Pads retain damping efficiency and mechanical stability under varying loads and temperatures.

The selected rubber materials prevent creep, deformation, and loss of isolation capacity. They perform reliably across industrial, commercial, and acoustic-sensitive floating floors, extending maintenance intervals and supporting long-term project performance.

Handling Extreme Loads and Environmental Conditions

FZPT-500 maintains vibration isolation even under heavy dynamic loads and extreme temperatures.

Its engineered elasticity supports heavy machinery without structural compromise.

The pad performs well in large-scale industrial applications, maintaining stability and damping capacity under extreme operational conditions. Its resilience ensures consistent isolation for floating platforms subjected to varying load conditions and environmental challenges.

Maintenance and Inspection Tips

Regular maintenance ensures maximum performance and longevity of FZPT-500 pads.

Periodic inspections, cleaning, and timely replacement prevent degradation and maintain optimal vibration control.

Recommended practices include checking for deformation, ensuring pads remain debris-free, and replacing worn units. Consistent care helps maintain isolation efficiency, reduces maintenance costs, and ensures long-term reliability in floating platform projects.